HP Scitex LX600 HP Scitex LX Printer Family - User's guide - Page 40

Load a roll onto the spindle, Single-roll printing, loading it into the printer.

|

View all HP Scitex LX600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

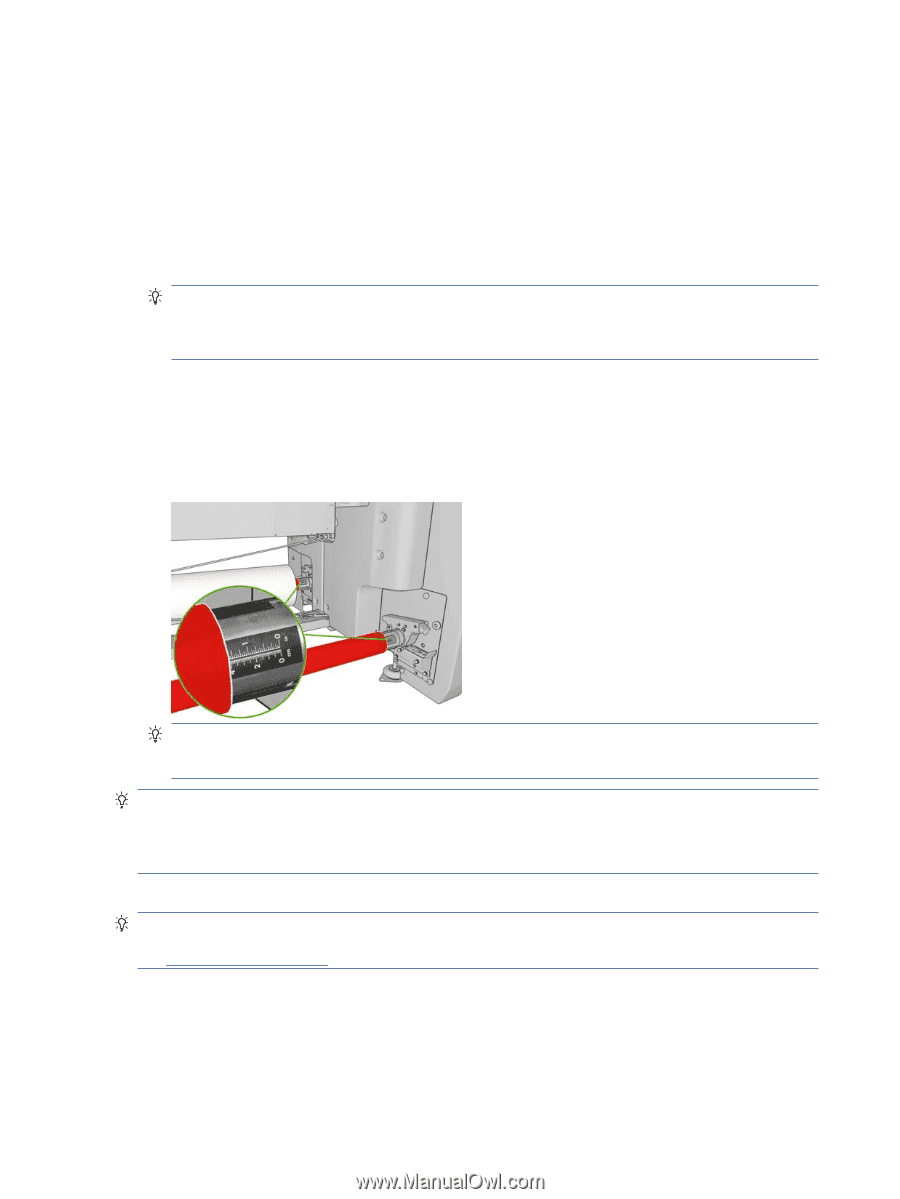

Load a roll onto the spindle Single-roll printing The spindle has a pneumatic connector at one end and a gear at the other. 1. Rest the roll securely on a trolley, a table or the floor. 2. Check that the gear is on the correct side (which depends on the intended winding direction). 3. Insert the spindle into the roll. TIP: The spindle is quite heavy in order to ensure stiffness and so avoid skew and wrinkles, so two people are recommended for this operation. With only one person, you are recommended to put the roll on the floor, lift one end of the spindle and insert it into the roll, then lift the other end carefully so that the first end does not fall out, and push the spindle into the roll. 4. Connect the air gun to the pneumatic connector on the spindle, and inflate the spindle so that it cannot move inside the roll. 5. Note the position of the end of the roll on the scale marked at the geared end of the spindle. Its position should be not less than 3.2 cm (1.25 in) on that scale, otherwise the substrate may go out of the print zone and start touching the printer covers. The input and output rolls should be positioned identically on their respective spindles. TIP: When loading heavy rolls of inelastic substrates that are approximately half the spindle length, you may find it useful to load the substrate closer to the center of the spindle, to reduce the risk of skew, wrinkles and telescoping. TIP: If the substrate is telescoped on the input roll, there is a risk of substrate jams and damage to the printheads. Try to straighten the edges of the substrate to minimize telescoping on the input roll before loading it into the printer. TIP: Check that the substrate is attached to the input core. The roll is now ready to be loaded into the printer. TIP: If you are a regular user of different substrate types, you can change rolls more quickly if you preload rolls of different substrate types on different spindles. Extra spindles are available for purchase, see Accessories on page 86. Dual-roll printing You can print on two rolls at the same time by using the dual-roll spindles provided with your LX800 printer or available as accessories for your LX600 printer. The dual-roll spindle is marked to assist you in positioning the differential hub. 36 Chapter 3 Handle the substrate ENWW