HP Scitex LX600 HP Scitex LX Printer Family - User's guide - Page 53

Load a roll (roll-to-free-fall configuration) (LX800 only)

|

View all HP Scitex LX600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

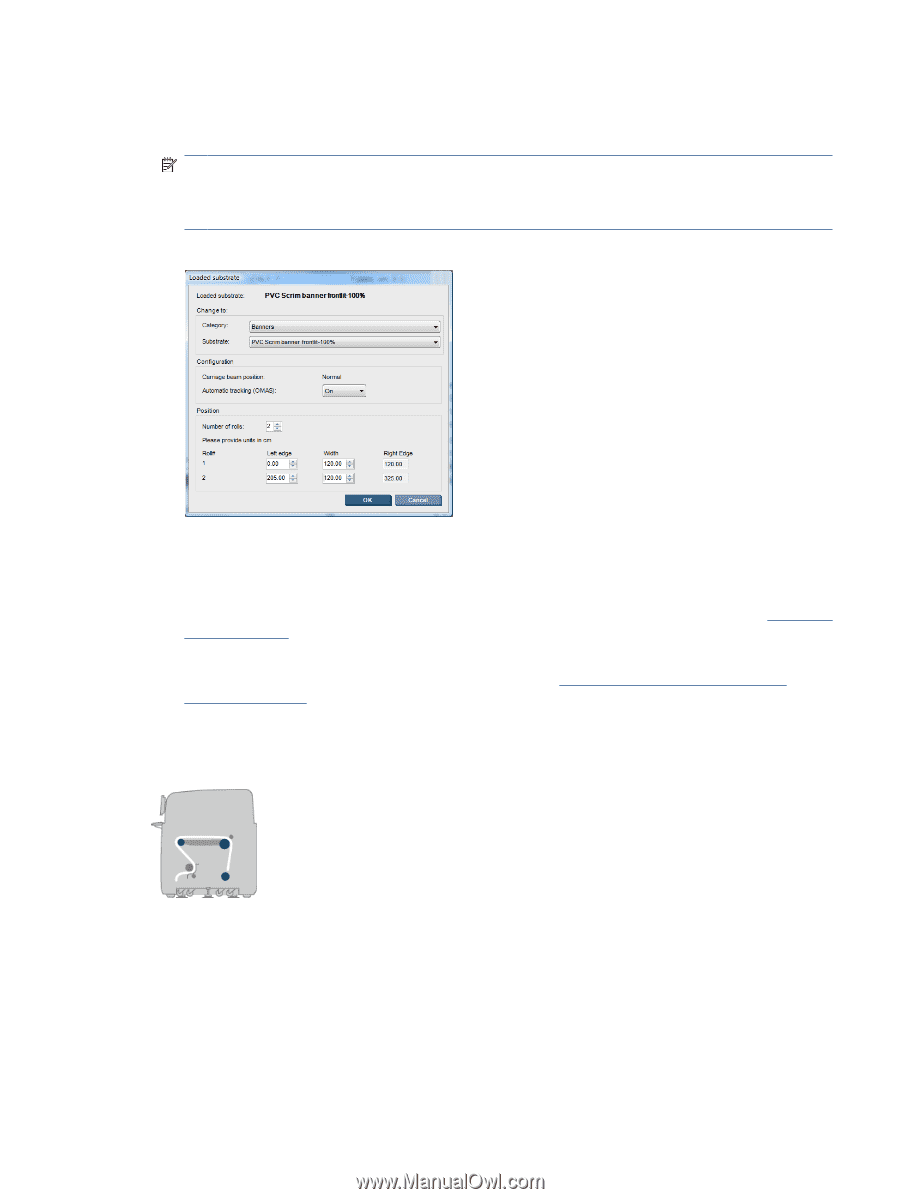

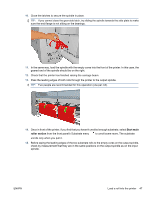

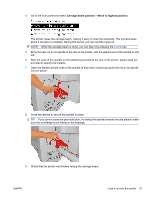

20. Go to the HP Internal Print Server and press the Load button. The printer rotates the rolls to check their diameters, and it also checks the width of the roll, the winding direction, the vacuum and the substrate advance calibration (this takes 1-2 min). NOTE: Some substrates (such as transparent substrates) cannot be measured by the printer in this way. In such cases, you will be asked to enter the required information manually. Use the scale on the curing module to see the value for the right-hand edge that must be entered manually in the HP Internal Print Server. 21. In the HP Internal Print Server, choose from the list of substrate types the type that you have loaded. The contents of the Loaded Substrate window are determined automatically when the substrate is loaded and checked. However, if the printer is unable to detect the edges of the substrate (for instance, in the case of a transparent substrate), you will have to measure the distance of the left edge from the printer's side plate, and complete the Left Edge and Width fields yourself. For more information on when you might want to change the carriage beam position, see Substrate tips on page 19. An alert regarding substrate advance tracking may appear at this point. For more information on when you might want to turn off automatic tracking, see Fine-tune the settings in your new preset on page 61 and the Maintenance and troubleshooting guide. The printer is now ready to print. Load a roll (roll-to-free-fall configuration) (LX800 only) The substrate roll is mounted on the rear spindle; the printed substrate will be deposited on the floor in front of the printer. The substrate goes from the rear spindle (1) over the main roller (3), over the platen, over the front roller (5) and then to the tension roller (7), after which it continues to the floor. The diverter rollers (2 and 6) and the ink collectors (4) are installed when printing on porous substrates. ENWW Load a roll into the printer 49