Brother International HL-3400CN Service Manual - Page 62

€13

|

UPC - 012502526223

View all Brother International HL-3400CN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

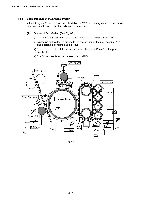

HL-3400CN SERVICE MANUAL (2) Variation of OPC Belt Potential (See Fig.4-10.) i) The OPC belt is initially biased to -CBV(V). ii) The OPC belt surface is evenly charged to Vo(V) in the charging process. iii) The potential of the exposure part of the OPC belt is reduced to -VR(V) as it is exposed to the laser beam in the process of exposing, and an electrostatic latent image is formed on the OPC belt as the result. iv) Negatively charged toner is moved onto the exposed part of the OPC belt in the development process due to the difference of potential between -VR(V) and DBV(V), and a visible toner image is formed as the result. v) Negatively charged toner on the OPC belt moves to the transfer drum surface in the transfer process because the GND potential of the transfer drum is greater than -VR(V) of the OPC belt. vi) The OPC belt is discharged by the erase lamp. Process • M OV OPC Belt -CBV \ 11 - VR DBV'' - Vo %\%% I IICharger T T CBV lailvI 4 l=> Transfer Drum GND Toner ii, ...... oner Dev. roller El Charging Process al Exposing Process al Developing Process El Transfering Process T [33 Cleaning (Erase) DBV CBV Power Supply for OPC Belt Bias 1:€13 Power Supply for Charging DBV Power Supply for Dev. Roller Bias nl Remain voltage on the OPC Belt Fig. 4-10 4-11