Epson 680Pro Service Manual - Page 120

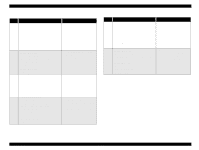

EPSON Stylus COLOR 680/777/777i, Revision B, Maintenance, Overview, Table 6-2. Lubrication Point

|

UPC - 010343832138

View all Epson 680Pro manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 120 highlights

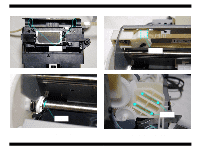

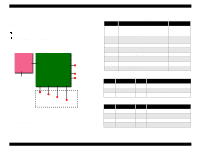

EPSON Stylus COLOR 680/777/777i Table 6-2. Lubrication Point No. Lubrication Type/Point Remarks • Inside the CR shaft hole of the CR unit. Refer to Figure 6-1, "Lubrication point 1". • Do not attach the grease to other portion of the CR unit. • Use a syringe to apply it. 1 • G-55 • Move the CR guide left and right, smooth out the Geese on the surface of the CR guide shaft. • Whole inside the CR shaft hole evenly. 40+/15mg x 2 • After lubrication, make sure that the carriage moves smoothly. • Contact point between PF roller and the PF grounding spring. Refer to Figure , "". • Do not attach the grease to the paper path. • Use a syringe to apply it. 2 • G-26 • Φ1mm x 5mm • Shaft of the Pully driven shaft. Refer to Figure 6-3, "Lubrication point 3". 3 • G-26 Φ1mm x 1mm • Use a syringe to apply it. • Use a syringe to apply it. • Inside the sliding slot for ASF Hopper on • After lubrication, move the ASF the ASF Frame.Refer to Figure 6-4, hopper manually and smooth out "Lubrication point 4". 4 the grease inside the ASF frame. • G-26 • Φ1mm x 4points Revision B Table 6-2. Lubrication Point No. Lubrication Type/Point Remarks • Use a syringe to apply it. • Specified both edges area on the Front • After lubrication, move the CR frame. Refer to Figure 6-5, "Lubrication unit left or right and smooth out point 5". 5 the grease on the Front frame. • G-26 • Φ1mm x 40mm x 2 areas • The Cam parts on the LD roller • Between the Cam parts on the LD roller shaft must touch the G-26 shaft and the ASF Hopper. Refer to Figure lubricated on the ASF hopper in 6-6, "Lubrication point 6". the LD roller shaft rotation. 6 • G-26 • Φ1mm x 1mm Maintenance Overview 120