Epson 680Pro Service Manual - Page 36

EPSON Stylus COLOR 680/777/77i, Revision B, Operating Principles, Overview,

|

UPC - 010343832138

View all Epson 680Pro manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

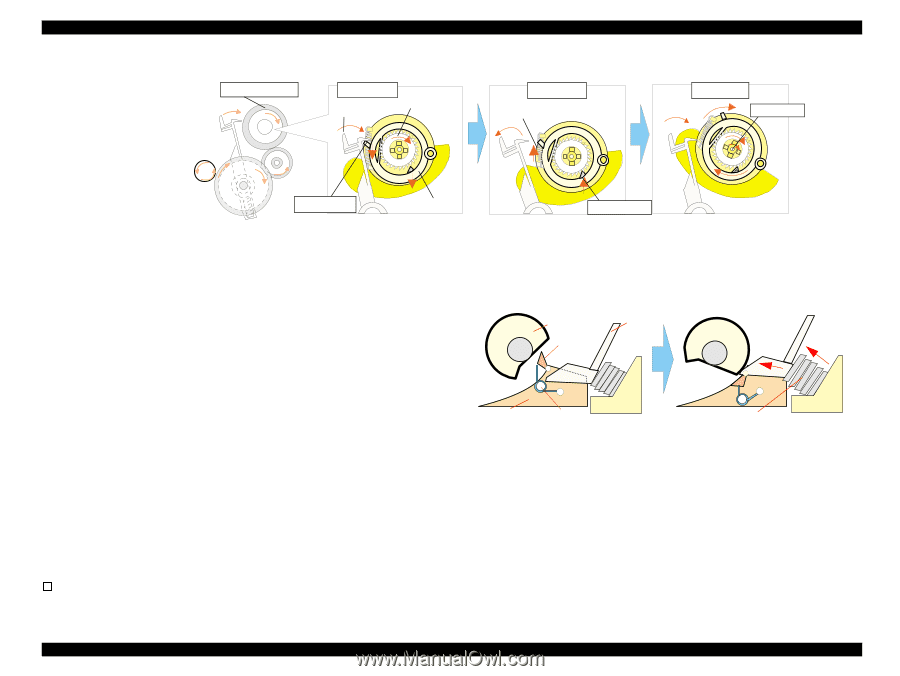

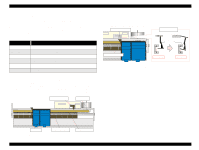

EPSON Stylus COLOR 680/777/77i Revision B NOTE: The Clutch gear is molded on the back side of the Spur gear 35.2 such as Combination gear. Spur gear 35.2 Step1 Change Lever Clutch gear Step2 Tension spring 0.143 Step3 LD roller shaft Clutch lever Clutch Figure 2-9. Disengage & Clutch mechanism Clutch lock tooth The Clutch mechanism transmits the PF motor drive to the LD roller shaft only when the Clutch gear rotates CW direction after the Change lever releases the Clutch lever. If the Clutch gear rotates CCW direction, the PF motor drive is not transmitted to the LD roller. This is due to the combination of the shape of the Clutch gear and the Clutch lock tooth such as described on the figure. 1. When the paper is advanced with the PF roller, the Change lever is set on the Clutch lever and the Clutch is pushed down as above Step1's figure. As the result, the Clutch gear (*1) is released from the Cluck lock tooth and the drive from the PF motor is not transmitted to the LD roller shaft. 2. When the PF pinion gear rotates CCW direction in the above Step2's figure, the Change lever moves to the left direction with the CCW rotation of Combination gear 37.6, 44.4. The Clutch turns back to the engagement position by the tension force of the Tension spring 0.143 and the Clutch gear is engaged with the Clutch lock tooth as above Step2's center figure. 3. When the PF pinion gear rotates CW direction in the above Step3's figure, the Change lever moves to the right direction with the CW rotation of the Combination gear 37.6, 44.4. And the drive from the PF motor is transmitted to the LD roller shaft via Clutch gear and Clutch lock tooth. 4. The LD roller shaft rotates about 360 degree and the Change lever push the Clutch lever and the PF motor drive is interrupted. This position is the ASF home position. o Paper Return Plate (Pad holder) Unlike the previous products, The Paper return plate is built in the ASF frame instead of the Paper return lever. The Paper separation pad is also stacked on the plate. It works with the spring force of the Torsion spring 25.7 (mounted in the ASF frame) as following figure. LD roller Hopper Paper Return Plate ASF frame Torsion spring 25.7 Compression spring 4.80 Figure 2-10. Paper Return Plate The Paper return plate is set to return the paper to the paper stand-by position in the ASF unit when the ASF unit is in the standby mode. When the paper is fed with the LD roller, the Paper return plate is stored in the ASF frame by the LD roller. Following figures show you the ASF paper loading sequence and the operation of the each mechanism. Operating Principles Overview 36