Brother International BAS-411 Instruction Manual - English - Page 17

Adjusting, timing, needle, rotary, cloth, presser, height

|

View all Brother International BAS-411 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

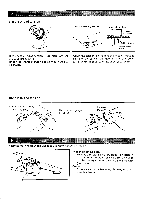

10 4 Adjusting timing of needle and rotary hook Figure A Aprrox. 1mm 4 f=1 tt I 1-• in I I r a) 2.3mm 0 (5-9:1-7) 1) Select the first needle bar 0. 2) Remove two screws and the needle plate 8. 3) When the needle bar is raised 2.3 mm (201°) above its lowest position (1801, loosen the screw 0 of the rotary hook 8, and adjust so that the needle meets the rotary hook point. Then, temporarily tighten the two stop screws. At this time, the needle bar height should be about 1 mm. (Figure A) 4) Select the ninth needle bar 0. If the gap between the needle and rotary hook point is 0.01 - 0.2 mm, tighten the three screws of the rotary hook. 2 Adjusting cloth presser height Cut and insert. 1-1.3 mm I I Adjust the cloth presser 0 height with the cushion rubber 6. The cloth presser 0 height should be raised 1 - 1.3 mm from the needle plate at the cloth presser's lowest position. (A sheet of the cushion rubber is 0.5 mm thick.) -13-