Brother International BES Lettering INSTRUCTION MANUAL - English - Page 135

Density, Design Workspace, Fill Stitch, Grouped Segments - bes embroidery lettering software 2

|

View all Brother International BES Lettering manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 135 highlights

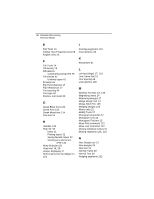

137 Density Density is the number of stitches covering a given area. Large letters, large fill areas and textured fabrics, generally need higher densities. The reverse can be true as well. There are two measuring systems used in calculating density: Imperial and Metric. The Imperial system measures density in stitches per inch (spi). 65spi means 65 stitches in a 1 inch (linear) area. The Metric system measures density in embroidery points (pt). Points refers to the distance between each thread. To increase density with the Imperial system, you increase the measurement number. With the Metric system, a higher number of points indicates a lower density. The following example shows what happens when you increase and decrease the density in embroidery points and stitches per inch. Design Workspace The design workspace includes the toolbars, menus, ribbon, and the design window containing the design you are editing. You can change the look and functionality of your design workspace by showing or hiding these elements. Fill Stitch Series of running stitches commonly used to cover large areas. Different fill patterns can be created by altering the angle, length, and repeat sequence of the stitches. Grouped Segments A collection of segments that work together as a single unit. Grouped segments can be ungrouped to access individual segments if the software being used allows this.