HP Z6100ps HP Designjet Z6100 Printer Series - User's Guide - Page 121

A summary of the color-management process

|

UPC - 882780990135

View all HP Z6100ps manuals

Add to My Manuals

Save this manual to your list of manuals |

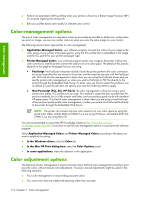

Page 121 highlights

Color management the need to handle the test print, provides repeatable drying times, and allows fast measurements with precise electromechanical positioning of the spectrophotometer over the color patch. This provides unprecedented ease of use and matches or exceeds the performance of more expensive offline, handheld profiling systems. A summary of the color-management process To get the accurate and consistent colors that you want, follow these steps for each paper type that you use. 1. If the printer does not recognize your paper type, add the type to the printer's list of known papers. See Use non-HP paper on page 47. Typical users might add a few custom paper types every year. 2. Color-calibrate the paper type to ensure consistent colors. Perform this calibration when a printer alert recommends this calibration (typically, every few weeks for each paper type you use). In addition, calibrate immediately before a particularly important print job in which color consistency is vital. 3. Color-profile the paper type to ensure accurate colors. Profiling does not normally need to be repeated; after you have a profile for a particular paper type, you can continue to use it. However, re-profiling does no harm, and some users repeat the profiling process every month to ensure that the profile is up-to-date. 4. When printing, select the correct color profile for the paper type that you are using. Paper types that are defined in the printer also have color profiles stored in the printer. However, HP recommends that you calibrate the paper before using it. If you define a new paper type, the printer automatically leads you through calibration and profiling. The following diagram shows the operations that the HP Color Center performs, in order. A summary of the color-management process 109