Ricoh SP C250DN Operating Instructions - Page 161

the Friction Pad and Paper Feed Roller

|

View all Ricoh SP C250DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 161 highlights

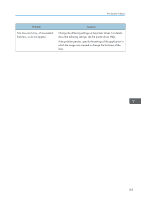

Paper Feed Problems Problem Multiple sheets of paper are fed at once. The printed paper is wrinkled. The printed paper is curled. Solution • Fan the paper well before loading. Also make sure that the edges are aligned by tapping the stack on a flat surface such as a desk. • Make sure that the paper guides are in the right position. • Use supported types of paper. See page 41 "Supported Paper". • Load paper only as high as the upper limit markings on the paper guide. • Make sure that the friction pads, paper feed rollers or registration rollers are clean. See page 144 "Cleaning the Friction Pad and Paper Feed Roller" and page 147 "Cleaning the Registration Roller and Paper Tray". • Check that paper was not added while there was still some left in the tray. Only add paper when there is none left in the tray. • The paper being used may be damp. Use paper that has been stored properly. See page 41 "Supported Paper". • Paper is too thin. See page 41 "Supported Paper". • If there are gaps between the paper and the paper guides, adjust the paper guides to remove the gaps. • Check that both the left and right fusing unit levers have been raised to the plain paper mark. • Load the paper upside down in the paper tray. • If the paper curl is severe, retrieve prints from the output tray more frequently. • The paper being used may be damp. Use paper that has been stored properly. See page 41 "Supported Paper". • Select [Level 2] or [Level 3] in [Anti-Humid Lvl] under [Maintenance]. Note that if you select [Level 2] or [Level 3], the first print takes longer than subsequent prints. 159