Ricoh SP C250DN Operating Instructions - Page 50

Paper can be loaded only up to the lower of the two paper limit marks of the tray. - black toner

|

View all Ricoh SP C250DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 50 highlights

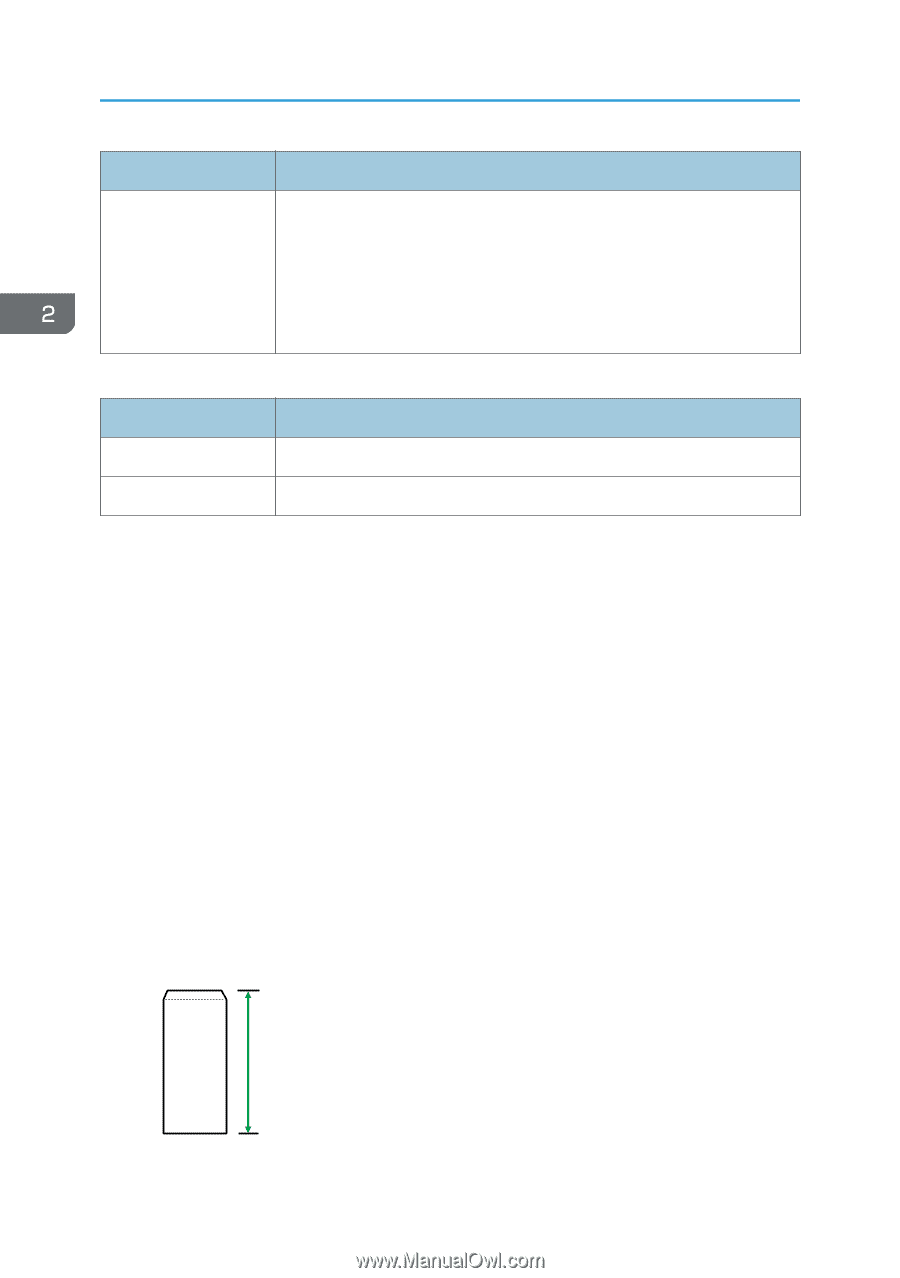

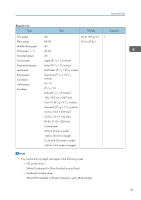

2. Loading Paper Item Notes Description • The number of sheets that can be printed per minute is approximately half that of middle thick paper. • Avoid using adhesive label paper on which glue is exposed. Glue may stick to the inner parts of the machine, which can cause paper feed problems, deterioration in print quality, or premature wear of the print cartridge's photo conductor unit. Envelope Item Supported paper tray Tray 1 and bypass tray Duplex supported size None Description Notes • Avoid using self-adhesive envelopes. They may cause machine malfunctions. • The number of envelopes that can be printed per minute is approximately half that of middle thick paper. • Paper can be loaded only up to the lower of the two paper limit marks of the tray. • If printed envelopes come out badly creased, load the envelopes in the opposite direction. Also, configure the printer driver to rotate the print object 180 degrees. For details about changing the orientation see the printer driver Help. • Environmental factors can degrade the print quality on both recommended and non-recommended envelopes. • If envelopes are severely curled after printing, flatten them by bending them back against the curl. • After printing, envelopes sometimes have creases along their long edges and toner smear on their unprinted sides. Print images might also be blurred. When printing large, black-solid areas, striping can occur as a result of the envelopes overlapping. • To correctly specify the length of an envelope whose flap opens along its short edge, be sure to include the open flap when measuring. 48 CER112