HP Scitex LX600 HP Scitex LX Printer Family - Maintenance and troubleshooting - Page 29

Clean the line sensor and aerosol inlets

|

View all HP Scitex LX600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

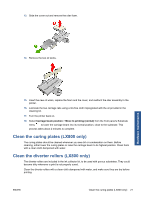

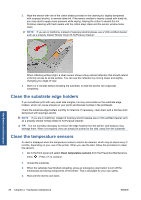

Clean the line sensor and aerosol inlets In the course of normal use, the line sensor becomes gradually blinded by light deposits of dried ink. An alert is displayed when the line sensor needs to be cleaned, which may be about every 2 months, depending on your use of the printer. When you see the alert, follow this procedure to clean the sensor. 1. Go to the front panel and select Clean line sens. & inlets from the Preventive Maintenance menu . 2. The printer raises the carriage beam so that you can access the sensor. 3. Wait for the front panel to announce that the sensor is ready for cleaning. 4. Dampen a cotton swab with isopropyl alcohol. Swabs are provided in the cleaning kit. NOTE: If you are in California, instead of isopropyl alcohol please use a VOC-certified cleaner such as a properly diluted 'Simple Green ® All-Purpose Cleaner'. 5. Reach underneath the line sensor and clean it with the cotton swab as shown. Hardware maintenance ENWW Clean the line sensor and aerosol inlets 23