HP Scitex LX600 HP Scitex LX Printer Family - Maintenance and troubleshooting - Page 47

The substrate is not attached to the input core, Substrate issues

|

View all HP Scitex LX600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

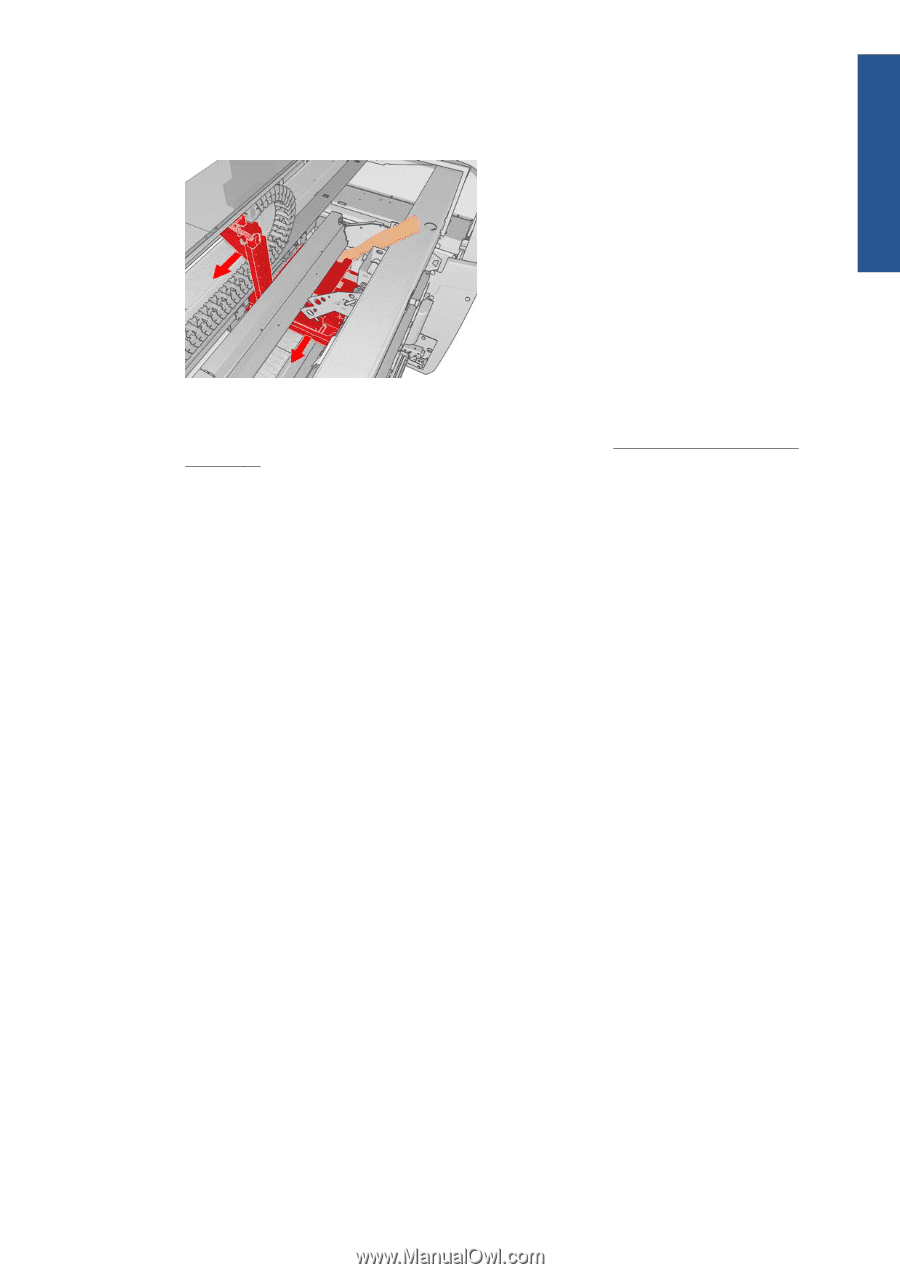

Substrate issues 3. If feasible, manually move the carriage slowly and carefully to the side, away from the substrate. If this is not feasible because of the severity of the jam, try raising the carriage beam to its maximum height. 4. Remove all substrate and pieces of substrate from the printing zone and from any other parts of the printer into which they may have fallen. Check the curing zone in particular. If you are unable to remove them all, please call your service representative (see HP Customer Care Centers on page 68). 5. Before restarting the printer and reloading the substrate, check that all circuit breakers are on and all emergency stop buttons released. The substrate is not attached to the input core If the printer detects a lack of tension during the substrate check after loading, it will ask you to confirm the winding direction. If the roll is not firmly attached to the input core during printing, you may see banding on your prints. If you see an error message numbered 78.2:01 while printing, it means that the substrate may have become detached from the rear spindle, or the core is slipping on the spindle. This could mean that you have reached the end of the roll, or the spindle is not correctly inflated, or the dual-roll differential hub is locked. The substrate is automatically unloaded when this error occurs. You should respond to this error in the following ways. ● Check whether you have reached the end of a roll. ● For single-roll printing, check that the spindle is correctly inflated. ● For dual-roll printing, check that the differential hub is unlocked. ● Check that the hubs are tightly secured to the spindle. ● Check that the diameter of each substrate core is not too large for the spindle. ● Check that each substrate core is tightly connected to the hubs on each side of it. ENWW The substrate is not attached to the input core 41