Lexmark C782 Service Manual

Lexmark C782 Manual

|

View all Lexmark C782 manuals

Add to My Manuals

Save this manual to your list of manuals |

Lexmark C782 manual content summary:

- Lexmark C782 | Service Manual - Page 1

Edition: November 7, 2008 Lexmark™ C77x, Lexmark C78x printer 5061 • Table of Contents • Start Diagnostics • Safety and Notices • Trademarks • Index Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries. - Lexmark C782 | Service Manual - Page 2

.com. Lexmark may use or distribute any of the information you supply in any way it believes appropriate without incurring any obligation to you. References in this publication to products, programs, or services do not imply that the manufacturer intends to make these available in all countries - Lexmark C782 | Service Manual - Page 3

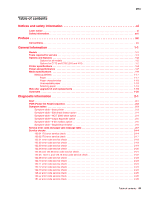

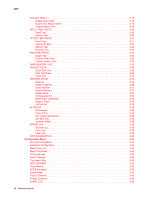

xi Laser notice xi Safety information xvii Preface xx Conventions xx General information 1-1 Models 1-1 Tools required for service 1-1 Options and features 1-2 Options for all models 1-2 Options for C772 and C782 (310 and 410 1-2 Printer specifications 1-4 Power and performance - Lexmark C782 | Service Manual - Page 4

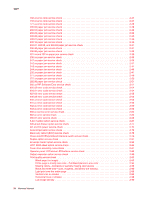

58 942.xx error code service check 2-60 943.xx error code service check 2-62 956.xx service error service check 2-64 982.xx error service check 2-64 990.01 error service check 2-65 5-bin mailbox option service check 2-67 500-sheet drawer option service check 2-71 AC and DC power service check - Lexmark C782 | Service Manual - Page 5

no error code displayed 2-102 Smudged or distorted images on fused page 2-102 Toner is on the back of the printed page 2-103 Light lines or streaks appear on the page 2-103 White streak in color plane 2-104 Paper wrapped around the second transfer roll 2-104 User troubleshooting for quality - Lexmark C782 | Service Manual - Page 6

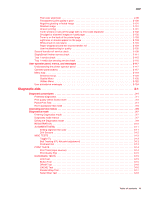

3-31 Exiting the Config Menu 3-31 Reset Fuser Cnt 3-32 Black Only Mode 3-32 Prt Quality Pgs 3-32 Color Trapping 3-32 Tray Insert Msg 3-32 SIZE SENSING 3-32 Panel Menus 3-33 PPDS Emulation 3-33 Demo Mode 3-33 Factory Defaults 3-33 Energy Conserve 3-33 EVENT LOG 3-33 vi Service Manual - Lexmark C782 | Service Manual - Page 7

Auto Color 3-43 Clearing mailbox, finisher, or output expander jams (Area M 3-43 Clearing fuser jams 3-44 Clearing image transfer unit jams 3-45 If you still need help 3-50 Repair information 4-1 Handling ESD-sensitive parts 4-1 Screw identification table 4-2 Removal procedures 4-6 - Lexmark C782 | Service Manual - Page 8

5-4 Cartridge contact assembly pin locations (black 5-5 System board cabling reference 5-6 Connectors 5-7 System board 5-7 Autoconnect-top 5-18 Autoconnect-bottom 5-19 Transfer high voltage power supply (HVPS 5-20 Developer high voltage power supply (HVPS) board 5-22 viii Service Manual - Lexmark C782 | Service Manual - Page 9

power supply (LVPS 5-23 LVPS cable connectors to system board 5-23 LVPS fuser connectors 5-24 Media size sensing board 5-25 High-capacity input tray (HCIT 5-26 StapleSmart finisher 5-28 Preventive maintenance 6-1 Safety inspection guide 6-1 Scheduled maintenance 6-1 Standard fusers 6-1 ITU - Lexmark C782 | Service Manual - Page 10

5061 Appendix A-Service tips A-1 Identifying the printheads A-1 Redrive belt routing A-2 Duplex option deflector button replacement A-3 Appendix B-Print quality samples B-1 Print Printhead electronic alignment test page-Magenta (two of two B-9 Index I-1 Part number index I-9 x Service Manual - Lexmark C782 | Service Manual - Page 11

operating in the wavelength region of 770-795 nanometers. The laser system and printer are designed so there is never any human access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service condition. Laser Der Drucker erfüllt gemäß amtlicher Best - Lexmark C782 | Service Manual - Page 12

galliumarsenid laser, som arbejder på bølgelængdeområdet 770-795 nanometer. Lasersystemet og printeren er udformet således, at mennesker aldrig udsættes for en laserstråling over Klasse I-niveau ved normal drift, brugervedligeholdelse eller obligatoriske servicebetingelser. xii Service Manual - Lexmark C782 | Service Manual - Page 13

i våglängdsområdet 770-795 nanometer. Lasersystemet och skrivaren är utformade så att det aldrig finns risk för att någon person utsätts för laserstrålning över Klass I-nivå vid normal användning, underhåll som utförs av användaren eller annan föreskriven serviceåtgärd. Laser-melding Skriveren er - Lexmark C782 | Service Manual - Page 14

3b) d'arseniür de gal.li, nominalment de 5 mil.liwats, i funciona a la regió de longitud d'ona de 770-795 nanòmetres. El sistema làser i la impressora han sigut concebuts de manera que mai hi hagi exposició a la usuari ni durant els serveis que satisfacin les condicions prescrites. xiv Service Manual - Lexmark C782 | Service Manual - Page 15

5061 Notices and safety information xv - Lexmark C782 | Service Manual - Page 16

5061 xvi Service Manual - Lexmark C782 | Service Manual - Page 17

and approvals of the original design and specific components. The manufacturer is not responsible for safety in the event of use of unauthorized replacement parts. • The maintenance information for this product has been prepared for use by a professional service person and is not intended to be - Lexmark C782 | Service Manual - Page 18

peligro y tomar las precauciones necesarias. • PRECAUCIÓN: este símbolo indica que el voltaje de la parte del equipo con la que está trabajando es peligroso. Antes de empezar, desenchufe el equipo o de estar ligado à corrente eléctrica para realizar a tarefa necessária. xviii Service Manual - Lexmark C782 | Service Manual - Page 19

producte. El personal professional ha d'estar-ne assabentat i prendre les mesures convenients. • PRECAUCIÓ: aquest símbol indica que el voltatge de la part de l'equip amb la qual esteu treballant és perillós. Abans de començar, desendolleu l'equip o extremeu les precaucions si, per treballar - Lexmark C782 | Service Manual - Page 20

locations and test points on the printer. 6. Preventive maintenance contains the lubrication specifications and recommendations to prevent problems. 7. Parts catalog contains illustrations and part numbers for individual FRUs. Appendix A contains service tips and information. Appendix B contains - Lexmark C782 | Service Manual - Page 21

to 3100 sheets. Models The Lexmark C77x and C78x (5061-xxx) laser printers are available in four models: Lexmark C770n Lexmark C772n Lexmark C780n Lexmark C782n 5061-110 5061-310 5061-210 5061-410 Network Network Network Network Tools required for service Flat-blade screwdriver #1 Phillips - Lexmark C782 | Service Manual - Page 22

Lexmark C77x and C78x printers support only Lexmark C77x and C78x paper-handling options. These options are not compatible with any other Lexmark printer. Note: The Envelope Feeder for the C772 (model 310) works only on the C772 the printer from the printer. The banner color • 500 MHz RISC - Lexmark C782 | Service Manual - Page 23

• After changing an image transfer unit (ITU) A manual calibration can be initiated by selecting Color Adjust from the Color Menu. Resolution • 1200 x 1200 dpi (one half printer speed) • 4800 CQ (default) (full printer speed) Toner darkness Toner darkness settings offer five user-selectable settings - Lexmark C782 | Service Manual - Page 24

Printer specifications Description Printer Lexmark C77x(n)/C78x(n) Lexmark C77xdn/C78xdn (including duplex option) Lexmark C77xdtn/C78xdtn (including duplex unit and optional 500-sheet drawer) Lexmark C772 lb (6.1 kg) 5.4 lb (2.5 kg) 8.7 lb (4.0 kg) 13 lb (5.6 kg) 20 lb (9.1 kg) 1-4 Service Manual - Lexmark C782 | Service Manual - Page 25

5061 Power and electrical specifications Average nominal power requirements for the base printer configuration (110 volt). (Power levels are shown in watts.) Maximum current shown in amp ergs. Printing states Lexmark C77x(n) Lexmark C77xdn Lexmark C78x(n) Lexmark C78xdn Printing-average power - Lexmark C782 | Service Manual - Page 26

(packaged printer) with or without print cartridge Temperature: -40 to 110° F (-40 to 43.3° C) • Print cartridge Temperature: -40 to 110° F (-40 to 43.3° C) *In some cases, performance specifications (such as paper OCF, EP cartridge usage) are measured at an ambient condition. 1-6 Service Manual - Lexmark C782 | Service Manual - Page 27

bin. Standby times may be longer if the toner control senses that toner flow needs to be checked or adjusted. Time to first print from standby mode • Black: - Lexmark C782 | Service Manual - Page 28

optional interface cards • Code expansion slot (application solution firmware cards) • On-board hard disk interface (for optional hard disk) Additional memory may be required for printing complex pages or full-page, high-resolution images in 1200 image quality at rated speeds. 1-8 Service Manual - Lexmark C782 | Service Manual - Page 29

specifications Media input and output capacities The capacities listed below are based on plain paper at 75g/m2. Media source or output description Capacity (sheets) Lexmark C770n, C770dn, Lexmark C770dtn Lexmark C772n, C772dn Lexmark C772dtn Lexmark C780n, C780dn Lexmark C780dtn Lexmark - Lexmark C782 | Service Manual - Page 30

Lexmark C770n, C770dn, Lexmark C770dtn Lexmark C772n, C772dn Lexmark C772dtn Lexmark C780n, C780dn Lexmark C780dtn Lexmark C782n, C782dn Lexmark supported support supported with size sensing † - supported 3 3 8 8 3 3 3 3 * Supported as selected paper with tray size sensing turned off in - Lexmark C782 | Service Manual - Page 31

8 104.8 mm x 210 mm 8 † 8 8 † 8 8 8 8 8 to 215.9 mm x 355.6 Other Envelope mm 4.125 in. x 8.27 in. to 8.5 in. x 14 in.) * Supported as selected paper with tray size sensing turned off in the appropriate trays. ** When selected, the page is formatted for 215.9 x 355.6 mm (8.5 x 14 in - Lexmark C782 | Service Manual - Page 32

Offset Staple 5061 Media support by type for optional features Legend 3 - supported 8- unsupported Media Transparencies 3 3 8 8 8 8 8 338 Paper and Vinyl 3 3 8 3 8 8 8 888 labels Envelopes 8 3 8 8 3 8 8 888 Glossy paper 3 3 3 3 8 8 8 888 1-12 Service Manual - Lexmark C782 | Service Manual - Page 33

supported Not supported Not supported Not supported Not supported Transparencies8 Laser printer 161 to 169 g/m2 161 to 169 g/m2 Not supported (43 to 45 lb bond) (43 to 45 lb bond) Not supported (68-90° F). 8 Lexmark transparency P/N12A8240 and 12A8241 are supported from the standard tray, - Lexmark C782 | Service Manual - Page 34

sensitive area must enter the printer first. 4 100% Lexmark transparency P/N12A8240 and 12A8241 are supported from the standard tray, optional 500-sheet trays, and the multipurpose feeder. 9 Paper 105 to 176 g/m2 (28 to 47 lb) must be printed with Paper Weight set to Heavy. 1-14 Service Manual - Lexmark C782 | Service Manual - Page 35

g/m2 (80 lb) Not supported Not supported Not supported Laser Transparencies printer 161 to 169 g/m2 Not supported 161 to 169 g/m2 161 to 169 g/m2 Not supported (43 to 45 lb label converter has passed the Lexmark criteria. Refer, also, to the Card Stock and Label Guide for more details. 9 Paper - Lexmark C782 | Service Manual - Page 36

Page and Automated FAX system (LEXFAX™) for information on whether your vinyl label converter has passed the Lexmark criteria. Refer, also, to the Card Stock and Label Guide for more details. 9 Paper 105-176 g/m2 (28-47 lb bond) must be printed with Paper Weight set to Heavy. 1-16 Service Manual - Lexmark C782 | Service Manual - Page 37

not supported in duplex. Paper less printer helps avoid printing problems. The following sections contain guidelines for choosing the correct media for the printer. For detailed information about media characteristics, see the Card Stock & Label Guide available on the Lexmark Web site at www.lexmark - Lexmark C782 | Service Manual - Page 38

chosen is acceptable for laser printers. When loading paper, Label Guide available on the Lexmark Web site at www.lexmark.com/publications. Weight The printer can automatically problems. Smoothness The degree of smoothness of paper directly affects print quality. If the paper is too rough, the toner - Lexmark C782 | Service Manual - Page 39

• Recycled papers containing more than 25% post-consumer waste that do not meet DIN 19 309 • Paper having a weight less than 60 g/m2 (16 lb) • Multiple-part forms or documents Selecting paper Proper paper loading helps prevent jams and ensures trouble-free printing. To help avoid jams or poor print - Lexmark C782 | Service Manual - Page 40

you to upgrade your current printer. Description Part number Web oiler upgrade kit 40X1856 The installation of the web oiler upgrade kit converts a standard Lexmark C77x printer to an oil web-capable printer. The web oiler upgrade kit includes an oiler fuser and web oiler. 1-20 Service Manual - Lexmark C782 | Service Manual - Page 41

Optical Sensor Photoconductor Picture element Power-On Reset Power-On Self Test Position Sensing Device Pulse Width Modulation Raster Imaging Processor Read Only Memory Synchronous Dual Random Access Memory Single Inline Memory Module Static Random Access Memory Toner Patch Sensing Used Parts Return - Lexmark C782 | Service Manual - Page 42

5061 1-22 Service Manual - Lexmark C782 | Service Manual - Page 43

can be found at the following locations: - "Understanding the printer operator panel" on page 2-117 - "Service checks" on page 2-14 Note: There may be printer error messages that are not contained in this service manual. Contact your next level of support for assistance. Diagnostic information 2-1 - Lexmark C782 | Service Manual - Page 44

the front cover assembly is closed, that a new or different toner cartridge has been installed. • The printer detects at power on when the cover is closed that a new or different ITU has been installed. • The printer detects at power on that the fuser temperature is below 60° C. • When coming out of - Lexmark C782 | Service Manual - Page 45

: Colored lines, streaks, or smudges Go to "925.02 error code service check" on page 2-54. Go to "927.03 error code service check" on page 2-55. Go to "926.01 error code service check" on page 2-54. Go to "Excessive fuser drive motor assembly noise" on page 2-87. Go to "AC and DC power service - Lexmark C782 | Service Manual - Page 46

2-101. Go to "Poor color alignment" on page 2-99. Go to "Toner is on the back of the printed page" on page 2-103. Go to "Toner smears or rubs off the page with no error code displayed" on page 2-102. Go to "Vertical lines or streaks" on page 2-98 Symptom Action Printer fails to recognize the - Lexmark C782 | Service Manual - Page 47

or no indication that bin x is near full." on page 2-92. Go to "Problems with excessive static electricity buildup." on page 2-92. "271.xx paper jam service check" on page 2-49. Symptom table-5-bin mailbox option Symptom Action Printer fails to recognize the option is installed. Paper Go to "The - Lexmark C782 | Service Manual - Page 48

the output tray. Go to "Stapled sheets are not transported to the output tray" on page 2-113. Finisher does not staple. Go to "StapleSmart finisher service check" on page 2-111 2-6 Service Manual - Lexmark C782 | Service Manual - Page 49

108.xx Printhead Error 109.xx Printhead Error 122.01 Fuser Error 122.02 Fuser Error 122.03 Fuser Error 122.04 Fuser Error 122.05 Fuser Error ITU belt track direction problem-go to "100.01 ITU error service check" on page 2-14. ITU belt tracking problem-go to "100.02 ITU error service check" on page - Lexmark C782 | Service Manual - Page 50

" on page 4-83. If this does not fix the problem, replace the system board. See "System board removal" on page 4-89. ITU belt motor error-go to "148.xx error code service check" on page 2-25. Fuser motor error-replace the fuser drive assembly. See"Fuser drive assembly removal" on page 4-46. If this - Lexmark C782 | Service Manual - Page 51

5061 Error codes and paper jam messages (continued) Error code Action 2xx paper jams 200.03 problem, go to "200.16 paper jam service check" on page 2-30. Laser paper path sensor obstructed. This message indicates that a paper jam has occurred at or near the printer input sensor. Open the printers - Lexmark C782 | Service Manual - Page 52

5061 Error codes and paper jam messages (continued) Error code 200.72 Paper Jam supported. Media has jammed at or before the fuser sensor. Open the printer lower right or center door to access the jammed media. If removing the jammed media does not fix the problem, go to "200.93 paper jam service - Lexmark C782 | Service Manual - Page 53

cause this type of error. Turn the printer off and on to try and clear the error code. If this does not fix the problem after several attempts, contact your next level of support before replacing the system board. Unrecoverable TPS Sensor Error-Replace the ITU assembly. See "ITU assembly removal" on - Lexmark C782 | Service Manual - Page 54

ITU assembly removal" on page 4-49. 925.02 Fan Stalled Fuser fan-Go to "925.02 error code service check" on page 2-54. 926.01 Fan Stalled VTB fan-Go to "926.01 error code service check" on page 2-54. 927.03 Fan Stalled RIP Fan-Go to "927.03 error code service check" on page 2-55. 930.09 LV Power - Lexmark C782 | Service Manual - Page 55

.xx Emulation Error Download emulation CRC failure has occurred. The following actions may be taken: 1. Disable the Download Emulation. 2. Program the download emulation into the code overlay SIMM again. 3. If the problem is not resolved, replace the code overlay SIMM and download emulation again - Lexmark C782 | Service Manual - Page 56

check" on page 2-67. Go to the service check for the device indicated. Service checks 100.01 ITU error service check A 100.01 ITU error indicates that the printer did not detect the ITU belt home sensor. Before proceeding with this service check, make sure that the Second Transfer Roll is correctly - Lexmark C782 | Service Manual - Page 57

roll installation. Is it installed correctly? Go to step 4 4 Check the display error log in the Diagnostic Menu. Is Go to "100.02 100.01 ITU preceded in the log by a 100.02 ITU Error? ITU error service check" on page 2-17. 5 Remove the ITU assembly and check that the sensor cable is seated in the - Lexmark C782 | Service Manual - Page 58

the MFP door to its horizontal position. Observe the gear on the left end of the ITU drive roll. The ITU drive roll gear should turn for a few seconds slowly and smoothly before the printer posts a 100.01 ITU error. Yes Go to step 10 No Go to step 9 Does the Gear turn? 9 Check to - Lexmark C782 | Service Manual - Page 59

100.02 ITU Error, so the belt is tracked off, and the customer or servicer turns off the printer to clear the error, when the printer starts up, it will still not see the belt signal and will now post a 100.01 ITU Error because the buffer is empty. When servicing a printer for a 100.01 ITU Error, it - Lexmark C782 | Service Manual - Page 60

printer must be setting on a solid, flat surface. Position the shield on top of the belt. Treat as a belt stall or signal communications problem. See "100.01 ITU error service check" on page 2-14. Has the ITU Belt shifted to the front or to the rear? 122.01 error code service check Hot fuser Error - Lexmark C782 | Service Manual - Page 61

service check Hot fuser Error code 122.02 displays whenever the printer detects a problem with the fuser running over temperature or the fuser lamps have been on too long. A problem could exist in the fuser assembly with the hot roll bearings, hot roll thermistor, or other hot roll parts. The LVPS - Lexmark C782 | Service Manual - Page 62

04 error code service check Cold hot roll Step 1 2 3 Actions and questions Measure the voltage on connector J17-11 on the system board. The voltage should measure approximately +0.13 V dc to +0.64 V dc as the hot roll lamp turns off and on. Is the voltage correct? Remove the fuser from the printer - Lexmark C782 | Service Manual - Page 63

5061 122.05 and 122.06 error code service check Error codes 122.05 and 122.-6 indicate that the fuser didn't increase in temperature enough. Error code 122.05 may also indicate a problem in the fuser assembly with the hot roll bearings, hot roll thermistor, LVPS, or the system board. Step 1 2 3 - Lexmark C782 | Service Manual - Page 64

error code service check Fuser assembly cam position is not found. Step 1 2 Actions and questions Observe the fuser drive assembly gears rotate during POR. Do the gears rotate? Do the gears stop and the fuser fuser from the printer. Measure the voltage at the DC fuser control connector on the LVPS - Lexmark C782 | Service Manual - Page 65

5061 122.08 error code service check Step 1 Actions and questions Replace the fuser assembly. See "Fuser assembly removal" on page 4-44. Does the error remain? Yes Replace the system board. See "System board removal" on page 4-89. No Problem resolved 122.10 error code service check Cold hot - Lexmark C782 | Service Manual - Page 66

89. Replace the LVPS assembly. See "LVPS assembly removal" on page 4-53. 122.12 error code service check Cold fuser If error code 122.08 displays, the printer has detected a problem in the fuser hot roll lamp circuity, fuser hot roll thermistor, system board, or LVPS fuser control circuits. Replace - Lexmark C782 | Service Manual - Page 67

5061 148.xx error code service check Step 1 2 3 4 5 6 Actions and questions Connector J16 on the system board-Check for correct installation of the ITU drive motor cable from the ITU drive motor to the system board connector J16. Is the cable connected correctly? ITU drive motor-Check for - Lexmark C782 | Service Manual - Page 68

Go to step 2 Go to step 3 Go to step 4 Problem resolved Problem resolved No Install the cable correctly. Install the cable correctly. Replace the black cartridge assembly cable. Go to step 5 Contact your next level of support. 151.xx error code service check Magenta cartridge drive assembly This - Lexmark C782 | Service Manual - Page 69

correctly. Go to step 4 Replace the cyan cartridge assembly cable. Problem resolved Go to step 5 Problem resolved Contact your next level of support. 153.xx error code service check Yellow cartridge drive assembly This error indicates that the yellow cartridge drive motor has failed to lock - Lexmark C782 | Service Manual - Page 70

error code service check This error indicates a MPF motor error .03 paper jam service check S2 sensor was made at an unexpected time. See "Printer sensors" on page the test. Is the problem resolved? Yes Clear the obstruction and reinstall or replace flag. Problem resolved No Go to step Service Manual - Lexmark C782 | Service Manual - Page 71

jam service check S2 or narrow media sensor did not break in time Note: See "Printer sensors" on page 5-3. Step Actions and questions 1 Make sure the media installed in the tray meets specifications. Does the media meet specifications? Yes Go to step 2 2 Check tray for the edge guide setting - Lexmark C782 | Service Manual - Page 72

Clear the paper path. No Properly load media. Contact your next level of support. No Inform the customer that media loaded in Tray x does not meet specification. Properly load media. Contact your next level of support. No Properly load media. Contact your next level of support. 2-30 Service Manual - Lexmark C782 | Service Manual - Page 73

The laser was made unexpectedly. Step 1 2 Actions and questions Remove fuser from printer, remove oiler housing from fuser, and pivot the paper guide up. Is paper jammed inside the fuser? Check fuser entry guide for toner buildup. Is toner built up on the fuser entry guide? 3 Check fuser exit - Lexmark C782 | Service Manual - Page 74

board removal" on page 4-89. Go to "Vacuum transport belt (VTB) removal" on page 4-95 to verify correct installation. Go to step 7. Go to step 8 Call the next level of support. Replace the vacuum transport belt. See "Vacuum transport belt (VTB) fan removal" on page 4-97. 2-32 Service Manual - Lexmark C782 | Service Manual - Page 75

3 Clear the jam. 201.xx and 202.xx paper jam service check Step 1 2 Actions and questions Remove the fuser from the printer. Remove the oiler housing from the fuser, and pivot the paper guide up. Is media jammed inside the fuser? Check fuser exit sensor flag. Does flag rotate freely and return to - Lexmark C782 | Service Manual - Page 76

if the jam occurred at duplex entry edge guide. Did the jam occur at the duplex entry edge guide? 9 If the duplex option is in use system board. 2. Replace the fuser assembly. See "Fuser assembly removal" on page 4-44. 3. Replace the LVPS assembly. See "LVPS assembly removal" on page Service Manual - Lexmark C782 | Service Manual - Page 77

service check Yes Check the following: • Reseat the option on the printer. • Verify the top cover is properly seated on developer HVPS. No Contact your next level of support on page 4-24. Go to step 8 Replace the fuser assembly. See "Fuser assembly removal" on page 4-44. Does the diverter operate - Lexmark C782 | Service Manual - Page 78

the duplex option. 241.xx paper jam service check 500-sheet drawer Media does not in the tray meets specifications. Does the media meet specifications? 2 Make sure from the Diagnostics menu to help diagnose a feed problem. See "Feed Test" on page 3-20. specifications. Load the media correctly. Go to step 4 - Lexmark C782 | Service Manual - Page 79

the following parts in the order until the error is service check For second installed tray/option. 500-sheet drawer option Media does not reach the pass thru sensor. Step 1 Actions and questions Is Tray 2 a HCIT 2000-sheet option? 2 Make sure the media installed in the tray meets specifications - Lexmark C782 | Service Manual - Page 80

the Tray x feed test from the Diagnostics menu to help diagnose a feed problem. See "Feed Test" on page 3-20. Is the media leaving the tray system board. Replace the option or replace the following parts in the order until the error is cleared: • Autocompensator pick assembly. See "Autocompensator - Lexmark C782 | Service Manual - Page 81

HCIT system board LED error code table" on page 2-84 to further isolate paper jam or sensor problems. Before proceeding with this service check, make sure ? 2 Make sure the media loaded in the paper tray meets printer supplies specifications and the media is loaded correctly. Make sure the side and - Lexmark C782 | Service Manual - Page 82

error code table" on page 2-84 to help isolate problems Feed unit assembly. Repair or replace parts as necessary. No Replace the problems found with the envelopes? Yes Inform the customer of the problems with the envelopes that do not meet specifications. No Go to step 2 2-40 Service Manual - Lexmark C782 | Service Manual - Page 83

worn or contaminated? 8 If you continue to have problems, replace the complete envelope option. Yes Go to Go to step 8 243.xx paper jam service check For third installed tray/option. 500- the media installed in the tray meets specifications. Does the media meet specifications? Yes Go to "HCIT" on - Lexmark C782 | Service Manual - Page 84

problem. error is cleared: • Autocompensator pick assembly. See "Autocompensator pick assembly removal" on page 4-27. • Tray x system board. No Load the media correctly. Go to step 5 Go to step 9 Go to step 7 Go to step 8 Install the cable correctly Install the cable correctly. 2-42 Service Manual - Lexmark C782 | Service Manual - Page 85

HCIT system board LED error code table" on page 2-84 to further isolate paper jam or sensor problems. Before proceeding with this service check, make sure ? 2 Make sure the media loaded in the paper tray meets printer supplies specifications and the media is loaded correctly. Make sure the side and - Lexmark C782 | Service Manual - Page 86

. Use the "HCIT system board LED error code table" on page 2-84 to help isolate problems in the feed unit assembly. Are you order shown: 1. HCIT system board. 2. Feed unit assembly. Repair or replace parts as necessary. No Replace the following FRUs in the order shown: 1. Registration Service Manual - Lexmark C782 | Service Manual - Page 87

of wear or contamination. Are the pick rolls worn or contaminated? 8 If you continue to have problems, replace the complete envelope option. Yes Inform the customer of the problems with the envelopes that do not meet specifications. Go to step 3 Go to step 8 Go to step 5 Go to step 6 Go to step - Lexmark C782 | Service Manual - Page 88

error code table" on page 2-84 to further isolate paper jam or sensor problems. Before proceeding with this service paper tray meets printer supplies specifications and the media "HCIT system board LED error code table" on page 2-84 in the paper tray does not meet specifications. Go to step 4 Go to - Lexmark C782 | Service Manual - Page 89

HCIT system board LED error code table" on page 2-84 to help isolate problems in the feed unit system board 2. Feed unit assembly. Repair or replace parts as necessary. No Replace the following FRUs in the does not meet specifications. Go to"Tray 1 service check" on page 2-115. Correct - Lexmark C782 | Service Manual - Page 90

on the friction buckler? Enter the Diagnostics Menu. Select INPUT TRAY TESTS, Sensor Test, and MP Feeder. Manually actuate the MPF sensor by moving the paper flag in the MPF. Does the test pass? Make sure "System board removal" on page 4-89. Replace the sensor cable assembly. 2-48 Service Manual - Lexmark C782 | Service Manual - Page 91

check Output bin Note: Before proceeding with this service check, run the Output Bin x Sensor Test and check for the failing sensor. Sensor Tests: XNF F P Near Full (Upper part of sensor assembly) Full (Lower part of sensor assembly) Pass Thru Sensor Step 1 2 3 4 Actions and questions DC - Lexmark C782 | Service Manual - Page 92

service check 5-bin mailbox Step 1 2 3 4 Actions and questions Bottom pass thru sensor flag-Make sure the flag is operating correctly and is not binding, broken, and there is no interference from the sensor cable. Is there any problem control board. Replace the sensor assembly. 2-50 Service Manual - Lexmark C782 | Service Manual - Page 93

should be checked first. Determine if the problem is constant or intermittent. Constant 900.xx errors Step 1 Actions and questions Reset the ITU electrical disconnect. Turn the printer off. Check the ITU release lever for correct operation. The ITU release lever is the black lever located on - Lexmark C782 | Service Manual - Page 94

the complete list by scrolling with the arrows ( or ). The code may be a very long string of characters and numbers, but is needed for analysis. Contact your next level of support. No Go to step 3 Go to step 4 Determine which option is causing the 900 error. Problem resolved 2-52 Service Manual - Lexmark C782 | Service Manual - Page 95

error? 6. Driver-What driver or driver level. With this information in hand, contact you next level of support. 900.xx Error Code displayed when the machine is connected to a network while still in Setup Required mode Step 1 Actions and questions Perform the following steps: 1. Power the printer - Lexmark C782 | Service Manual - Page 96

fuser fan. See "Fuser fan removal" on page 4-47. Install the cable correctly. Replace the system board. See "System board removal" on page 4-89. Are the voltages correct? 926.01 error code service check VTB fan Step 1 Actions and questions Turn the power off, manually "Vacuum transport belt (VTB) - Lexmark C782 | Service Manual - Page 97

03 error code service check RIP fan Step 1 Actions and questions Turn the power off, manually spin error code service check LVPS This problem with the fuser circuits is usually the zero crossover signal from the LVPS not working correctly. Step 1 2 Actions and questions LVPS cable-check the LVPS - Lexmark C782 | Service Manual - Page 98

the LVPS assembly. See "LVPS assembly removal" on page 4-53. No Problem resolved 940.xx error code service check • 940.02-cyan toner metering cycle (TMC) problem • 940.05-cyan toner metering timeout problem The TMC is where the code and electronics in the printer sense an addition of toner in - Lexmark C782 | Service Manual - Page 99

contact block and the developer HVPS. Note: You may need to turn the printer off to hear the click. Does the cyan TMC switch on the developer mounting of the developer HVPS. Make sure the screws that mount the power supply are properly tightened down and the board is positioned and mounted correctly - Lexmark C782 | Service Manual - Page 100

HVPS to system board cable. 941.xx error code service check • 941.03-magenta toner metering cycle (TMC) problem • 941.05-magenta toner metering cycle timeout problem The TMC is where the code and electronics in the printer sense an addition of toner in the cartridge developing area. If the - Lexmark C782 | Service Manual - Page 101

contact block and the developer HVPS. Note: You may need to turn the printer off to hear the click. Does the magenta TMC switch on the developer of the developer HVPS. Make sure the screws that mount the power supply are properly tightened down and the board is positioned and mounted correctly - Lexmark C782 | Service Manual - Page 102

cable. 942.xx error code service check • 942.04-yellow toner metering cycle (TMC) problem • 942.05-yellow TMC timeout problem The TMC is where the code and electronics in the printer sense an addition of toner in the cartridge developing area. If the printer is expecting a toner addition cycle but - Lexmark C782 | Service Manual - Page 103

contact block and the developer HVPS. Note: You may need to turn the printer off to hear the click. Does the yellow TMC switch on the developer of the developer HVPS. Make sure the screws that mount the power supply are properly tightened down and the board is positioned and mounted correctly - Lexmark C782 | Service Manual - Page 104

developer HVPS to system board cable. 943.xx error code service check • 943.01-black toner metering cycle (TMC) problem • 943.05-black TMC timeout problem Toner metering cycle (TMC) is where the code and electronics in the printer sense an addition of toner in the cartridge developing area. If the - Lexmark C782 | Service Manual - Page 105

contact block and the developer HVPS. Note: You may need to turn the printer off to hear the click. Does the black TMC switch on the developer of the developer HVPS. Make sure the screws that mount the power supply are properly tightened down and the board is positioned and mounted correctly - Lexmark C782 | Service Manual - Page 106

982.xx error service check Step Actions and questions 1 Are the output options not recognized? 2 Remove the output option, and reinstall it on the printer. Power on the printer. Does this fix the problem? 3 Remove the input option, and reinstall it on the printer. Power on the printer. Does this - Lexmark C782 | Service Manual - Page 107

5061 990.01 error service check This error indicates which option is causing the error. 5-Bin mailbox Step Actions and questions 1 Mechanical linkage/DC motor assembly-Check the DC motor cable connector to make sure it is installed at J4 - Lexmark C782 | Service Manual - Page 108

Service Error-Tray x, x=Tray 2, 3, or 4, this is the tray that has a problem or needs service. Note: Verify the autoconnect housing is correctly snapped into the printer Check for worn or broken parts in the autocompensator and drive assemblies. Are any parts worn, broken, or damaged? Service Manual - Lexmark C782 | Service Manual - Page 109

. 3 272.xx Paper Jam-Check Bin 1 message Yes Go to "Problems with excessive static electricity buildup." on page 2-92. Go to "The printer does not recognize one or more output options as installed." on page 2-68. Go to "272.xx paper jam service check" on page 2-50. No Go to step 2 Go to - Lexmark C782 | Service Manual - Page 110

. 272.xx Paper Jam- check bin 1 message" on page 2-70. Go to 950.xx Error Code service check. No Go to step 5 Go to step 6 Go to step 7 Go to step 8 Contact your next level of support. The printer does not recognize one or more output options as installed. Step 1 2 3 4 Actions and questions - Lexmark C782 | Service Manual - Page 111

printer autoconnect connector- Turn the power off, and remove the output option from the printer. Check the voltages on the base printer flag-check the bin x sensor flag for binding and proper operation. Are there any problems with the sensor flag? 4 Bin x sensor cable-Check the continuity of the - Lexmark C782 | Service Manual - Page 112

problem, parts or repairs necessary. Replace the solenoid assembly. Replace the 5-Bin Mailbox control board assembly. Replace the mechanical linkage/DC motor assembly. No Go to step 2 Go to step 3 Replace bin x solenoid assembly. Replace the 5-Bin Mailbox control board assembly. 2-70 Service Manual - Lexmark C782 | Service Manual - Page 113

does not feed from the 500-sheet option, see "Autocompensator service check" on page 2-76. Whenever the 500-sheet tray is the autoconnect from the printer or option above tray x. Check for cuts, pinched wiring, or damage to the contacts in the connector. Are there any problems with the autoconnect - Lexmark C782 | Service Manual - Page 114

parts loose, broken, or missing? Yes Go to step 2 Problem resolved Go to step 4 Repair or replace as necessary. No Go to step 3 Go to step 3 Install the bellcrank correctly. Contact your next level of support. The printer . Install the paper level sensing assembly correctly. 2-72 Service Manual - Lexmark C782 | Service Manual - Page 115

5061 The printer detects paper out in installation. Check the following for damaged or broken parts: • Paper level sensing flag bellcrank • Paper assembly. Recheck the arm. If the problem continues, replace the paper leveling sensing assembly. If the problem still persists, replace the tray x system - Lexmark C782 | Service Manual - Page 116

power service check" on page 2-74. No Go to "DC power service check" on page 2-75. AC power service check The printer appears to be inoperative when turned on with the Power on/Status LED off, the LCD display is blank, the fuser voltage power supply-Turn the power off, and disconnect the LVPS at - Lexmark C782 | Service Manual - Page 117

the printer, and plug in the cable for the component that is related to the error presented. For example, for the 109.xx Service Printhead error, plug in the black printhead JMMK1 and JMK1. Use connector locations on "System board" on page 5-7. Repeat this step until the original DC power problem - Lexmark C782 | Service Manual - Page 118

is out or low, go to "Step D" on page 2-78. Note: When feeding paper through the printer to check for autocompensator problems, use the Tray 1 Feed test in the Diagnostics Menu. A printed copy is not required. Step A the system board. See "System board removal" on page 4-89. 2-76 Service Manual - Lexmark C782 | Service Manual - Page 119

Yes Replace tray 1. No Go to step 2 Repair or replace parts as necessary. Go to step 3 Dislodge the autocompensator assembly. Replace the Step 1 2 Actions and questions Can you remove Tray 1 from the printer? Open the lower jam access door, carefully lift the autocompensator assembly until - Lexmark C782 | Service Manual - Page 120

. Does the ITU belt move up and down when the ITU is toggled? 2 Remove the ITU. Locate the BOR gear, and manually activate the gear. Verify that the front and back BOR cams are moving the respective bell cranks. Do the cams move back and forth properly? Yes Go to "Print quality service check" on - Lexmark C782 | Service Manual - Page 121

mounted in the front access door support, and the other switch in the printhead/open cover cable is mounted on the ITU light shield assembly. The HVPS/cover cable assembly" on page 7-37 for the part number.) Replace the ITU light shield assembly. See "ITU light shield assembly" on page 7-37. - Lexmark C782 | Service Manual - Page 122

printer feeds blank page This symptom is usually associated with the upper switch mounted on the front access door support. Step Actions and questions 1 Make sure that the ITU light shield is not broken. Is the ITU light shield broken? 2 Make sure that the ITU for part number.) 2-80 Service Manual - Lexmark C782 | Service Manual - Page 123

with this service check: for any signs of loose, damaged, contaminated, or warped parts that might cause a jam. Duplex not recognized as being installed 2 The problem is in one of the option(s) that is installed beneath the printer. Try to isolate which of the options is causing the problem. Go to - Lexmark C782 | Service Manual - Page 124

continuity? Go to step 10 Replace the duplex options board. No Replace the bottom options cable in the printer. Correctly install the cable. If the connector is damaged, replace the cable assembly. Install the cable 19 to adjust the top margin on the back of the duplexed page. 2-82 Service Manual - Lexmark C782 | Service Manual - Page 125

complete assembly with no other internal parts that can be replaced. If a 24x.xx paper jam is displayed, go to the appropriate service check: • 242.xx-go to "Envelope feeder" on page 2-40 • 243.xx-go to "Envelope feeder" on page 2-45 The printer does not - Lexmark C782 | Service Manual - Page 126

of damage to the tray or parts in the tray? Yes Go to step 2 No Install the tray correctly. Go to step 3 Set the tray up correctly. Replace the envelope feeder tray. Replace the envelope feeder option. HCIT 2000-sheet option service check HCIT system board LED error code table If a failure is - Lexmark C782 | Service Manual - Page 127

+5 V dc Are the voltages correct? 5 Autoconnect cables-Check the autoconnect from the printer or option above the HCIT 2000-sheet option. Check for any signs of cuts, damage to the contacts in the connector. Are there any problems with the autoconnect cables? 6 HCIT autoconnect cable-Check the - Lexmark C782 | Service Manual - Page 128

service check, make sure the 2000-sheet tray option is properly connected to AC power. The printer power cord plugs into the HCIT AC outlet, and the power LVPS. Is the voltage correct? Check the AC cable from the HCIT AC inlet to the LVPS system board. Replace the HCIT LVPS. Determine where the AC - Lexmark C782 | Service Manual - Page 129

missing? 5 Check the media size sensor flag for sticking or broken parts. Is the media size sensor flag sticking or broken? 6 Check continuity problem, replace the HCIT system board. No Load the media properly, or inform the customer that the media does not meet specifications. Reinstall the guide - Lexmark C782 | Service Manual - Page 130

assembly-Is the operator panel assembly completely blank and the power on status LED on? 6 Does the printer beep 5 times? Yes Go to step 2 No Go to step 4 Problem resolved Replace the operator panel assembly. see assembly. See "Operator panel assembly removal" on page 4-68. 2-88 Service Manual - Lexmark C782 | Service Manual - Page 131

Operator panel assembly-Does the operator panel display all diamonds, with the power on/status LED on and five beeps? 13 Voltage checks at system board 4-68 and replace the operator panel cable. Contact your next level of support. Go to step 14 Go to "Operator panel assembly removal" on page 4-68 - Lexmark C782 | Service Manual - Page 132

service the unit. Step 1 2 3 4 5 6 7 Actions and questions The printer Service-Bin x Yes Go to "Printer does not recognize that one or more output options as being installed." on page 2-91. Go to "271.xx paper jam service paper jam service check" on to "990.01 error service check" on page - Lexmark C782 | Service Manual - Page 133

cables. The problem is in the base printer. Check autoconnects in the printer. Replace the output operation, binds, broken parts, or interference from the sensor cable. Is there a problem with the sensor flag of support. No Go to step 2 Replace the sensor assembly. If this does not fix the problem, - Lexmark C782 | Service Manual - Page 134

the sensor. No Install the cable correctly. Contact your next level of support. Replace the control board. Problems with excessive static electricity buildup. Step 1 Actions and questions Excessive static electricity cover assembly if the ESD brush is loose or damaged. 2-92 Service Manual - Lexmark C782 | Service Manual - Page 135

the correct settings to check for print quality. • If a specific color has a print quality problem, first try a new cartridge to help isolate the problem. An incorrect printer driver for the installed software can cause print quality problems. Incorrect characters could print, and the copy may not - Lexmark C782 | Service Manual - Page 136

laser path between the printhead and cartridge for the color that is experiencing the full bleed issue. Does the issue still persist? Turn the printer operate correctly? 6 Turn the printer off. Check the cable connections the cartridge. Go to step 5 Problem resolved Replace the system board. See - Lexmark C782 | Service Manual - Page 137

color planes • If a color or colors are missing, or a color same plane is missing or faded on the ITU belt? 4 Turn off the printer. Check the cable connections between the transfer HVPS Go to step 3 Go to step 6 Problem resolved Replace the FRUs in the following order: 1. Cable 2. FTR - Lexmark C782 | Service Manual - Page 138

the user or network administrator to check if the correct color driver is installed. Is the correct color driver installed? Yes Change the setting to Color. Install the correct color driver. No Go to step 2 Go to "Black only retract (BOR) service check" on page 2-78. Light print over the entire - Lexmark C782 | Service Manual - Page 139

" on page 4-91. No Problem resolved Problem resolved Check the connection at the second transfer roll arm. One color has light print over the entire cartridge seated correctly? 2 Print cartridge-The cartridge may be out of toner. Change or switch the cartridge. Does the issue persist? 3 Cartridge - Lexmark C782 | Service Manual - Page 140

ITU maintenance kit. See "Scheduled maintenance" on page 6-1. Replace the cartridge. Replace the "Cartridge contact assembly removal for the failing color on page 4-35. Replace the "ITU assembly removal" on page 4-49. No Go to step 2 Go to step 3 Go to step 4 Problem resolved 2-98 Service Manual - Lexmark C782 | Service Manual - Page 141

menus, especially if the printer has been previously serviced. Was color calibration disabled? Toner density calibration-Run toner density calibration from the Utility menu. Does this fix the problem? Yes Set Color Calibration on. No Go to step 2 Problem resolved Replace the transfer HPVS - Lexmark C782 | Service Manual - Page 142

right side of the printer. This is visible by removing the yellow print cartridge. Is the ITU seated correctly? Yes Alignment- Enter the Diagnostics Menu. Perform the alignment for the color required. See "ALIGNMENT MENU" on page 3-11. No Reinstall the ITU. If the problem continues, replace the - Lexmark C782 | Service Manual - Page 143

or streaks that are different on each page. The most likely cause for this type of problem is damage to the ITU belt in the ITU assembly. Replace the "ITU assembly removal" on page 4-49. • If only one color is missing or printing uneven, go to step 1. Step 1 2 Actions and questions Print cartridge - Lexmark C782 | Service Manual - Page 144

5061 Toner smears or rubs off the page with no error code displayed Note: This type of problem is associated with improper fusing or incorrect settings for media type being used. Step 1 Actions and questions Media settings-Does the media setting match the - Lexmark C782 | Service Manual - Page 145

to High fix the problem? Yes Set the printer for current media type, and go to step 2. Problem resolved Problem resolved No Go to step 3 Go to step 3 Replace the fuser assembly. See "Fuser assembly removal" on page 4-44. Light lines or streaks appear on the page Single color streaks outside the - Lexmark C782 | Service Manual - Page 146

roll, again? Yes Remove the piece of media, and go to step 2. No Problem resolved Replace the second transfer roll. See "Second transfer roll removal" on page 4-88. If this does not fix the problem, contact your next level of support for assistance. Problem resolved 2-104 Service Manual - Lexmark C782 | Service Manual - Page 147

not correct the problem, call for service. You may have a printer part that requires adjustment or replacement. Quality troubleshooting Symptom Repeating defects Cause Either the print cartridges are defective, the image transfer unit and transfer roller are defective, or the fuser is defective - Lexmark C782 | Service Manual - Page 148

Replace the color print cartridge causing the streaks. Print irregularities ABCDE ABCDE ABCDE • Paper has absorbed moisture due to high humidity. • You are using paper that does not meet the printer specifications. • The image transfer unit and transfer roller are worn or defective. • The fuser is - Lexmark C782 | Service Manual - Page 149

5061 Quality troubleshooting (continued) Symptom Cause Solution Print too light • Paper settings may be incorrect. • The Toner Darkness setting is too light. • You are using paper that does not meet the printer specifications. • The print cartridges are low on toner. • The print cartridges are - Lexmark C782 | Service Manual - Page 150

media in the tray. • Move the guides in the tray to the proper positions for the size loaded. • Refer to the Card Stock & Label Guide available on the Lexmark Web site at www.lexmark.com for detailed specifications. • For more information, see "Media guidelines" on page 1-17. 2-108 Service Manual - Lexmark C782 | Service Manual - Page 151

? Transfer arms, springs, and associated hardware- Contact your next level of support. None of these parts are service related parts. Is there any problem with the associated hardware? Transfer high voltage power supply, HV wiring, and contacts-Check the second transfer cable (transfer HVPS contact - Lexmark C782 | Service Manual - Page 152

color(s) that is having transfer problems. Is the ITU bias spring broken, off, or missing? 6 Check the transfer HVPS to ITU HV transfer terminal for the color(s) that is having transfer problems removal" on page 4-88. 3) ITU assembly. See "ITU assembly removal" on page 4-49. 2-110 Service Manual - Lexmark C782 | Service Manual - Page 153

service check Note: When removing the stapler mechanism from the option, first remove the staple supply cartridge. Note: When replacing staples in the supply cartridge, discard any old staples in the cartridge, and replace with a fresh strip. Problems . Replace the printer top options autoconnect - Lexmark C782 | Service Manual - Page 154

access door for any signs of damage or broken parts. Make sure the door correctly actuates the stapler side access door switch. If this does not fix the problem, replace the stapler option. Does the side cover door into output tray but not stapled Replace the stapler option. 2-112 Service Manual - Lexmark C782 | Service Manual - Page 155

cycle or fire. • 990.01 Service displayed. Step 1 2 3 the stapler assembly: 1. Turn the printer off, and remove the right assembly for damaged or broken parts. Check the flag and may be necessary to manually cycle the large gear on page 3-23. Does the problem persist? Stapler to stapler board - Lexmark C782 | Service Manual - Page 156

holder is jammed in the stapler assembly: 1. Turn the printer off, and remove the right side cover. Use care when . 4. Check the stapler assembly for damaged or broken parts. Check the flag and spring assembly on the front Problem resolved Replace the stapler board cable (J3). 2-114 Service Manual - Lexmark C782 | Service Manual - Page 157

with the tray being correctly installed. Is there anything in the printer that might cause the tray from installing correctly? Yes Repair or replace parts as necessary. Go to step 3 Replace the paper tray guide. Repair or replace parts as necessary. Go to step 6 Replace the tray assembly. Repair as - Lexmark C782 | Service Manual - Page 158

5061 Tray 1 media size sensing service check The printer does not sense the size of the media installed in Tray 1. Note: If there is a problem when installing Tray 1, Tray 1 is difficult to remove or does not stay locked in position, go to "Tray 1 service check" on page 2-115. Step Actions and - Lexmark C782 | Service Manual - Page 159

Press the Back button to return to the last screen viewed. Note: Changes made on a screen will not be applied if you press the Back is used on the operator panel. The lights indicate whether the printer power is on, the printer is busy, idle, processing a job, or requires operator intervention - Lexmark C782 | Service Manual - Page 160

and the Supplies (Warnings) status. If multiple warnings are present, each warning will be separated by a comma. The other three lines of the display are the body of the screen. This is where you view printer status, supplies messages, Show me screens, and make selections. 2-118 Service Manual - Lexmark C782 | Service Manual - Page 161

these values at any time, but they only affect printer function when you have the optional equipment or the specified printer language. Supplies Menu Cyan Cartridge Magenta Cartridge Yellow Cartridge Black Cartridge Waste Toner Box Fuser ITU Paper Menu Default Source Paper Size/Type Configure MP - Lexmark C782 | Service Manual - Page 162

overrides Toner Darkness settings. Color Saver is not supported in PPDS, and partially supported by the PCL emulation driver. On Off (default) To assist in making brightness, contrast, and saturation adjustments to color output. These functions do not affect files where CMYK color specifications - Lexmark C782 | Service Manual - Page 163

Yellow Black Reset Defaults Color Samples Manual Color To assist users in selecting colors to be printed. Users can print color samples pages for each of the RGB and CMYK color conversion tables used in the printer. The color samples pages consist of a series of colored boxes along with the RGB - Lexmark C782 | Service Manual - Page 164

Web Server. On Off (default) In the driver, enable the check box. In the driver, disable the check box. Utilities Menu Use this menu selection to change printer settings, remove jobs, set up printer hardware, and troubleshoot printer problems. Utilities Menu Menu selection Factory Defaults - Lexmark C782 | Service Manual - Page 165

in hexadecimal and character representation. Control codes are not executed. Note: To exit Hex Trace, turn the printer off, or reset the printer by pressing Stop ( ). Percent coverage is not printed. Prints the estimated percentage of coverage for each color on a page. 5 is the default setting - Lexmark C782 | Service Manual - Page 166

The printer is clear. Cartridge Low Specified toner cartridge is low. refers fully connected to the printer or is experiencing a printer off and back on. If the error recurs, go to "982.xx error service The printer is leaving Demo printer off while this message is displayed. DO NOT POWER - Lexmark C782 | Service Manual - Page 167

POWER OFF Engine Warming Enter PIN Enter PIN to lock Error printing from USB drive Error reading USB drive Flushing buffer Formatting Disk yyy% DO NOT POWER OFF Formatting Flash DO NOT POWER PIN you identified in the driver when you sent the confidential job to the printer. Enter the correct PIN to - Lexmark C782 | Service Manual - Page 168

Menu. The following functions are available using the Busy/Waiting Menu. - Cancel Job - Reset Printer - Reset Active Bin - Check Supply Levels Download valid engine code to the printer. Note: You can download engine code while this message is displayed. The selected file on the USB device is not - Lexmark C782 | Service Manual - Page 169

another PIN. • Select Cancel to exit the Enter PIN screen. No jobs to cancel Wait for the message to clear. No recognized file types Wait for the message to clear. Note: The only supported file type is PDF. Not ready The printer is offline. Press to return to normal operation. Overflow Bin - Lexmark C782 | Service Manual - Page 170

device. • In the case of a hardware failure, turn the printer off and back on. If the error recurs, got to "982.xx error service check" on page 2-64. Remote Management Active DO NOT POWER OFF The printer settings are being configured, and the printer was taken offline to ensure it is not currently - Lexmark C782 | Service Manual - Page 171

Replace the waste toner bottle. 1565 Emul Error Load Emul Option The printer automatically clears the message in 30 seconds, and then disables the download emulator on the firmware card. Download the correct download emulator version from the Lexmark Web site. 30 toner cartridge missing - Lexmark C782 | Service Manual - Page 172

fix the problem. Press to clear the message. If the Service Printer message is displayed, it means that a TPS failure has most likely occurred. The printer continues to operate, but the color quality degrades. The most probable cause for this error message is a defective print cartridge or ITU. This - Lexmark C782 | Service Manual - Page 173

too complex to print 40 [color] invalid refill, change cartridge This message is displayed when insufficient printer memory is available to perform Printer - Reset Active Bin - Check Supply Levels Note: Menu Lockout does NOT prevent access to the Busy/Waiting Menu. Replace the specified toner - Lexmark C782 | Service Manual - Page 174

similar font, and this error does not occur. This error also displays when the printer receives invalid PPDS download font data. This error only occurs when a printer is formatting PPDS print data. Other data streams support different protocols for handling the font errors. The following actions can - Lexmark C782 | Service Manual - Page 175

received on the USB port is discarded. • Press Menu to access the Busy/Waiting Menu. The following functions may be available: - Reset Printer - Reset Active Bin - Check Supply Levels Note: Menu Lockout does NOT prevent access to the Busy/Waiting Menu. Note: Make sure the USB Buffer menu item is - Lexmark C782 | Service Manual - Page 176

Too many trays attached 58 Input Config Error 59 Incompatible duplex 59 Incompatible output printer. 2. Remove the additional trays. 3. Plug in the printer, and turn it on. This message is displayed when: • An high-capacity input tray (HCIT) is connected when it is not supported (C770 Service Manual - Lexmark C782 | Service Manual - Page 177

(continued) User primary message 63 Unformatted disk 82 Waste toner box nearly full 82 Replace Waste toner box 82 Waste toner box missing 83 ITU missing Explanation • Press to clear the message and continue printing. • Format the disk. If the error message remains, the hard disk may be defective - Lexmark C782 | Service Manual - Page 178

5061 2-136 Service Manual - Lexmark C782 | Service Manual - Page 179

printer failures and verify repairs have corrected the problem. Diagnostic procedures Printhead diagnostics If you get a printhead error, follow this diagnostic to find the specific are properly seated and the error remains, record the error code. Continue to the next step. Diagnostic aids 3-1 - Lexmark C782 | Service Manual - Page 180

board removal" on page 4-89. If that solves the problem, you are finished. Make sure you return all the cables to the original positions. • If the printer displays a different printhead error code, which indicates the code for the other color of the pair you switched, the printhead or the printhead - Lexmark C782 | Service Manual - Page 181

portrait orientation for the test file. Printing the chart from the user menu The printer has an internal copy of the defect locator chart under the Help Menu. At the defect locator chart, go to the back of the hard copy service manual. Note: If you want to copy the chart, then the following should - Lexmark C782 | Service Manual - Page 182

printer off. 2. Remove all cartridges and the ITU. 3. Inspect the bellcranks. 4. Enter the Configuration Menu. See "Configuration Menu" on page 3-31. 5. Select Prt Quality Pgs, and press Select. 6. Open the vacuum transport belt • Toner cartridge-Switch cartridges to determine if the problem stays - Lexmark C782 | Service Manual - Page 183

Continuity on the bell crank circuit-Turn the printer off. Using a multimeter, check the continuity between the rear bell crank contact for the failing color and the respective cable on the transfer HVPS board. See "Transfer high voltage power supply (HVPS)" on page 5-20. • Transfer HVPS cable-Make - Lexmark C782 | Service Manual - Page 184

that can be accessed during POR to identify problems with the printer. Diagnostics Mode 1. Turn off the printer. 2. Press and hold and . The Diagnostics Mode group contains the settings and operations used while manufacturing and servicing the printer. See "Diagnostics mode" on page 3-7 for more - Lexmark C782 | Service Manual - Page 185

the printer. 4. Hold the buttons about 10 seconds (until the clock face appears). Diagnostic mode menus REGISTRATION Top Margin Bottom Margin Left Margin Right Margin Quick Test ALIGNMENT Cyan Yellow Magenta Factory Scanner Factory Manual Drift Sensors MISC TESTS Toggle ITU Belt Tracking Printhead - Lexmark C782 | Service Manual - Page 186

Disk Test Disk Test/Clean Flash Test PRINTER SETUP Defaults PAGE COUNTS Serial Number Engine Setting 1-4 Model Name Configuration ID Reset Color Cal Edge to Edge Cal Ref Adj See "Configuration ID" on page 3-27 See "Reset Color Calibration" on page 3-28 See "Edge to Edge" on page 3-28 See "Cal Ref Adj - Lexmark C782 | Service Manual - Page 187

DC Charge Adjust Dev Bias Adj Transfer Adjust EVENT LOG Display Log Print Log Clear Log EXIT DIAGNOSTICS See "EP Defaults" on page 3-28 See "Fuser Temp" on page 3-28 See "DC Charge Adjustment" on page 3-28 See "Dev Bias Adj" on page 3-28 See "Transfer Adjust" on page 3-28 See - Lexmark C782 | Service Manual - Page 188

Use ALIGNMENT to align the individual colors. The black image should be aligned before the individual colors are aligned. To set Registration: the margin values are correct, print the Quick Test Page from the registration screen. Press to print the test page. While printing, Quick Test Printing... - Lexmark C782 | Service Manual - Page 189

to use to determine page registration. • Horizontal lines help to adjust skew • General printer information, including current page count, installed memory • Specific information including serial number, code level and print registration settings The Quick Test is printed from the default paper - Lexmark C782 | Service Manual - Page 190

. The following screen is displayed when Error Open Short Range Number Description: Communication is good RIP to A/D communication error Open thermistor error Short thermistor error Range error problem, replace the system board. To exit the test, press Back ( ) or Stop ( ). 3-12 Service Manual - Lexmark C782 | Service Manual - Page 191

and close all covers before initiating this test, and note the belt position. 1. Remove the cartridges from the printer, and close all covers. 2. Select Belt Tracking from the menu. The following screen is displayed: Belt Tracking Testing... The operation normally takes approximately 15 minutes to - Lexmark C782 | Service Manual - Page 192

test; press any button. 5. Verify the failure code by comparing the belt position to the initial position. Install the shim to the rear if the belt tracked to the rear. Install the shim to the font if the belt tracked to the front. Refer to the instructions included with the shim for installation - Lexmark C782 | Service Manual - Page 193

cannot be canceled. When the test pages print the printer returns to the original screen. HARDWARE TESTS LCD Test This test verifies the operator panel each operator panel button one at a time, and an "X" displays in the box that represents the button. If you press Back or Stop, you exit the test - Lexmark C782 | Service Manual - Page 194

mode. The power indicator blinks indicating the test is in progress and Reseting the Printer and DRAM Test Testing... appears on the screen. The printer resets, errors. Initially 000000 is displayed. The maximum fall count is 999,999. 2. To exit the test, turn the printer off. 3-16 Service Manual - Lexmark C782 | Service Manual - Page 195

2. Select the Parallel Wrap Test from HARDWARE TESTS in the Diagnostics mode. The power indicator blinks, indicating the test is in progress. The test runs continuously until canceled. Each time the test finishes, the screen updates. If the test passes, the Pass Count increases by 1. However, if the - Lexmark C782 | Service Manual - Page 196

Data 422 Error FIFO Error DSR Error DSR PIO Error DSR Interrupt Error CTS Error CTS PIO Error CTS Interrupt Error Once the maximum count is reached, the test stops. The power indicator goes on solid and the final results are displayed. Press Back ( ) or Stop ( ) to exit the test. 3-18 Service Manual - Lexmark C782 | Service Manual - Page 197

be canceled. • The printer attempts to print the Quick Test Page from the default paper source. If the default paper source only supports envelopes, then the the sensor to test: Duplex input sensor Duplex exit sensor 3. Manually actuate the duplex sensors. When the sensor/switch is closed, Closed - Lexmark C782 | Service Manual - Page 198

to access the paper jams on the vacuum transport belt. Blank pages feed during the test. Note: This test can run using any of the paper or envelope sizes supported by the printer. The pages are placed in the default output be in this position. See "For 2000-sheet trays" below. 3-20 Service Manual - Lexmark C782 | Service Manual - Page 199

sensor Input trays side cover sensor 2. Manually actuate each tray sensor by moving the printer setting is link rather than mailbox, the printer selects its own internal bin linking regardless of which output bin is selected for the feed test. This test verifies that media can be fed to a specific - Lexmark C782 | Service Manual - Page 200

following output sources, if installed, are supported by this test. Standard Bin Output full. 3. Once the selection is displayed, you can manually actuate the sensor you want to test. When the sensor test checks all of the diverters installed on the printer. When the test is selected from OUTPUT BIN - Lexmark C782 | Service Manual - Page 201

sheet fed for this test is blank. Any size paper that is supported can be used. You can also the test is complete, the printer returns to the original screen. Finisher Sensor Test This test polled: • Once the sensors are polled, you can manually actuate each of the sensors. When the sensor is closed - Lexmark C782 | Service Manual - Page 202

inside the printer are operating correctly. The following sensors can be checked using this test: Input-In-Line Media Clear Input-S2 Media Clear Fuser Exit Media displayed, depending on the sensor. 3. Manually toggle the sensors by hand to verify that each sensor switches from open to closed. 3- - Lexmark C782 | Service Manual - Page 203

the test, press Select ( ). If is selected, Disk Test/Clean/BAD:000000 00% is displayed. The screen updates periodically, indicating the percentage of test completed and the number of bad blocks found. 3. The power indicator blinks during the test. The test can be canceled anytime during the test by - Lexmark C782 | Service Manual - Page 204

PRINTER SETUP in the Diagnostics mode. 2. Select either Color Page Count or Mono Page Count. When you have made the selection, a screen similar to the following is displayed: Color return to PRINTER SETUP. 6. Select a new test or select Exit Diagnostics from the Diagnostic Menu. 3-26 Service Manual - Lexmark C782 | Service Manual - Page 205

to the following screen displays when permanent page count is selected: Perm Page Count =1234567* 3. Press Back ( ) to return to PRINTER SETUP in the Diagnostics mode. Serial Number You can view the serial number. Engine Setting x Warning: Should not be changed without specific instructions from the - Lexmark C782 | Service Manual - Page 206

is displayed: Resetting Calibration 2. The printer returns to the previous screen when calibration is complete. Edge to Edge Turn Edge to Edge printing on or off. Cal Ref Adj Warning: Should not be changed without specific instructions from the next level of support. EP SETUP EP Defaults The EP - Lexmark C782 | Service Manual - Page 207

specific printer. The printout of the log contains the following information for each error in the log: • Page count when the error occurred (except for 900 service RIP software errors). • Code versions of all packages when error occurred. • Panel display when error occurred (except for 900 service - Lexmark C782 | Service Manual - Page 208

Yes to clear the Event Log or No to exit the Clear Log menu. If Yes is selected, the Empty Event Log displays on the screen. 3. Press Back ( ) or Stop ( ) to exit the Clear Log menu. EXIT DIAGNOSTICS Select EXIT DIAGNOSTICS to exit the Diagnostics mode and return to normal mode - Lexmark C782 | Service Manual - Page 209

2. Press and hold and . 3. Turn on the printer. 4. Hold the buttons about 10 seconds (until the clock face appears). The following are available from the Configuration Menu: Configuration Menu Reset Fuser Cnt Black Only Mode Prt Quality Pgs Color Trapping Tray Insert Msg SIZE SENSING Panel Menus - Lexmark C782 | Service Manual - Page 210

printer posts a fuser maintenance message on the operator panel. 1. Select Reset Fuser this test to identify print quality problems. The Test Pages must be PostScript printing. 1. Select Color Trapping from the Config . Only paper sources that support Auto Size Sensing are displayed Service Manual - Lexmark C782 | Service Manual - Page 211

On or Off. EVENT LOG The history of printer errors can be printed by selecting Print Log. Note: This log can be printed from Diagnostics mode or the Configuration Menu, but the report from Configuration menu contains the debug and secondary error codes that are not printed in the version from the - Lexmark C782 | Service Manual - Page 212

If the printer detects a new or different color cartridge is installed, usually at power on or when the cover is closed. • If the printer detects a new or different ITU is installed, usually at power on or when the cover is closed. • If the fuser detects at power on that the fuser temperature is at - Lexmark C782 | Service Manual - Page 213

the settings are changed, all data on the hard disk is deleted. Exit Config Menu Press Select to exit the Configuration menu and reboot the printer. Diagnostic aids 3-35 - Lexmark C782 | Service Manual - Page 214

, the appropriate jam message will be displayed on the printer operator panel. If you select Show areas on the operator panel, you can view one or more images to help you Jam 24.xx Paper Jam Area C Paper input options: 500-sheet drawer or 2000-sheet drawer 24.xx Paper Jam 3-36 Service Manual - Lexmark C782 | Service Manual - Page 215

, paper may be caught in the fuser. For instructions, see Clearing fuser jams. Follow the instructions for clearing Area K and Area L. If the jam message persists, paper may be caught in the fuser. For instructions, see Clearing fuser jams. Follow the instructions for clearing Area E and Area - Lexmark C782 | Service Manual - Page 216

message to clear certain printer areas. After you have cleared the following areas, make sure all printer covers, doors, and trays are closed, and then press to resume printing. Note: The printer also displays Pages the feeder to its working position, and reload your media. 3-38 Service Manual - Lexmark C782 | Service Manual - Page 217

Area B 1. Open the left access door until it latches open. 5061 2. Remove all visible media. Note: Remove any torn media from the printer. 3. Close the door. Note: Open Tray 1, and make sure the entire media stack is pushed all the way down into the tray. Area C If you - Lexmark C782 | Service Manual - Page 218

. 2. Close the door. Area D 1. Open the front access door. 2. Hold down the front access door. Remove jams in the rollers under the image transfer unit. Note: Any image printed will not be fused to the page. Area T1 1. If clearing Area B did not clear the - Lexmark C782 | Service Manual - Page 219

1. Pull the duplex tray E completely out. Look inside, and remove any paper caught in the rollers. Also, look up inside, as some jams may be above the rollers. 2. Reinstall the duplex mechanism in the printer. Area T If you cannot clear all the 500-sheet drawer jams from Area C: 1. Carefully open - Lexmark C782 | Service Manual - Page 220

5061 Area J 1. Remove the duplex tray J. 2. Remove any jams, and then reinstall the tray. Area K 1. Open the lower right access door. 2. Remove any jams, and then close the door. 3-42 Service Manual - Lexmark C782 | Service Manual - Page 221

Area L 1. Open the upper right access door. 5061 2. Remove jams from the rollers, and then close the door. Clearing mailbox, finisher, or output expander jams (Area M) 1. Open the rear door of the 5-bin mailbox or output expander. 2. Pull - Lexmark C782 | Service Manual - Page 222

access doors (Areas K and L). CAUTION The fuser assembly may be hot. Let it cool before continuing. 3. Pull down the latches. They slide toward the center to release the fuser. 4. Pull the fuser out, and set it on a clean, flat surface. 5. Unsnap the housing, and set it aside. 3-44 Service Manual - Lexmark C782 | Service Manual - Page 223

cover, and remove the jam. 5061 7. Close the fuser roller cover. 8. Snap the housing back onto the fuser. 9. Insert the fuser back into the printer. 10. Slide the latches out, and then pull up to refasten them. 11. Close the doors. Clearing image transfer unit jams 1. Open the front access - Lexmark C782 | Service Manual - Page 224

printer off. Open the front cover assembly. 5. Remove all the print cartridges. a. Pull up slightly on the cartridge handhold. b. Pull the cartridge straight out, and use the handle to lift it off the guides. c. Place the cartridges on a clean, flat surface out of direct light. 3-46 Service Manual - Lexmark C782 | Service Manual - Page 225

6. Release the latches to open the multipurpose feeder (area A) all the way. 5061 7. Remove the image transfer unit. a. Raise the lever to unlock the image transfer unit. b. Pull down on the handle. Diagnostic aids 3-47 - Lexmark C782 | Service Manual - Page 226

the transfer belt. Touching the belt will damage the image transfer unit. 8. Look inside the printer. Remove all torn paper or other jams. 9. Insert the image transfer unit back into the printer. a. Align the guides with the insertion grooves, and gently slide the unit in. 3-48 Service Manual - Lexmark C782 | Service Manual - Page 227

b. Rotate the handle up, and push gently to lock the unit in place. 5061 c. Lower the lever to lock the image transfer unit into place. Diagnostic aids 3-49 - Lexmark C782 | Service Manual - Page 228

5061 10. Return the multipurpose feeder to its working position. Reinstall all the print cartridges. 11. Close the printer door. 12. Turn the printer on. The printer returns to a Ready state. If you still need help Turn the printer off and then back on. 3-50 Service Manual - Lexmark C782 | Service Manual - Page 229

to electrostatic discharge (ESD). To prevent damage to ESD-sensitive parts, use the following instructions in addition to all the usual precautions, such as turning off power before removing logic boards: • Keep the ESD-sensitive part in its original shipping container (a special "ESD bag") until - Lexmark C782 | Service Manual - Page 230

rear cover to LVPS HVPS standoffs to upper frame Mounting 7 Attach 1 Mounting 4 133 M3x8 mm Door handle to cover Panhead Detent housing to cover Door spring shields to cover Attach 2 Attach 1 Attach 4 214 M3.5x10 mm ITU motor to gearbox Machine Mounting 4 4-2 Service Manual - Lexmark C782 | Service Manual - Page 231

to terminal (BOR/ITU) yellow Attach 1 Thermistor to printheads Attach 8 Guides to V-blocks Attach 8 323 M3.5x8 mm Frame support back plate to lower frame Attach 2 Plastite Thread Forming Door latch catch to frame Attach 2 Transfer HVPS to lower frame Mounting 2 Fuser top duct to - Lexmark C782 | Service Manual - Page 232

Mounting 2 Fuser top duct to lower frame Mounting 1 Tray interlock bellcrank to lower frame Attach 1 Front left light shield to upper front cover Mounting 2 and front left handle assembly Card support plate to frame Mounting 2 Card shield to lower frame Mounting 3 4-4 Service Manual - Lexmark C782 | Service Manual - Page 233

Forming Front left light shield to left upper cover Attach 1 asm and top cover Front right light shield to right front cover Attach 1 support and top cover Cartridge drive assemblies to upper frame Mounting 12 Upper door hinges to upper frame (redrive) Attach 2 Inner redrive assembly to - Lexmark C782 | Service Manual - Page 234

Make sure your fingers are not under the printer when you lift or set the printer down. Note: Some removal procedures require removing cable ties. You must replace cable ties during reassembly to avoid pinching wires, obstructing the paper path, or restricting mechanical movement. 4-6 Service Manual - Lexmark C782 | Service Manual - Page 235

panel bezel with overlays-2xx only", "Operator panel bezel with overlays-3xx only", or "Operator panel bezel with overlays-4xx only" on page 7-3 for the part number. 1. Open the front cover assembly. 2. Remove the two small screws (A). A 3. Close the front cover assembly. Repair information 4-7 - Lexmark C782 | Service Manual - Page 236

5061 4. Lift the bezel out and then straight up. Note: Be careful not to swing the bezel out too far and break off the clips. Note: Set the lens (B) aside. It is not part of the bezel FRU. 4-8 Service Manual - Lexmark C782 | Service Manual - Page 237

Lens removal See "Clear LCD lens" on page 7-3 for the part number. 1. Remove the bezel. See "Operator panel bezel removal" on page 4-7. 2. Remove the lens (A). 5061 Repair information 4-9 - Lexmark C782 | Service Manual - Page 238

5061 Front cover rear pivot cover removal See "Front cover rear pivot cover" on page 7-3 for the part number. 1. Remove the bezel. See "Operator panel bezel removal" on page 4-7. 2. Remove the four screws (A). 3. Remove the front cover rear pivot cover. 4-10 Service Manual - Lexmark C782 | Service Manual - Page 239