Lexmark C782 Service Manual - Page 78

xx paper jam service check, the Duplex Sensor test. See

|

View all Lexmark C782 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 78 highlights

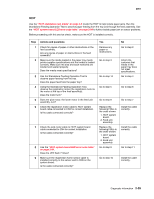

5061 Step 6 7 8 9 Actions and questions Check that the diverter actuator link is not binding or damaged. Examine the link for damage under the duplex option. Is link binding or damaged? Check the duplex actuator button. See "Duplex option deflector button replacement" on page A-3. Should the button be replaced? Check for the correct sensor operation by performing the Duplex Sensor test. See "Duplex Sensor Test" on page 3-19. Make sure the sensors are correctly connected to the duplex system board. Are the cables correctly connected? Yes Repair the actuator link. Replace the actuator button. Replace the duplex option. Replace the duplex option. 241.xx paper jam service check 500-sheet drawer Media does not reach the pass thru sensor. No Go to step 7 Go to step 8 Go to step 9 Correctly connect the cables. Step 1 Actions and questions Make sure the media installed in the tray meets specifications. Does the media meet specifications? 2 Make sure the media is loaded correctly. Make sure the side and back restraints are located and seated properly. Is the media loaded correctly? 3 See if the paper is trying to feed from the tray. Note: You can observe the autocompensator feed rolls and the paper through the tray access door. Run the Tray x feed test from the Diagnostics menu to help diagnose a feed problem. See "Feed Test" on page 3-20. Is the media leaving the tray? 4 Are both of the autocompensator pick rolls installed and turning? 5 Check the autocompensator pick rolls for wear or contamination. Are the autocompensator pick rolls worn or contaminated? 6 Check the pass thru sensor for correct operation by running the Tray x sensor test from the Diagnostics Menu. See "Sensor Test" on page 3-20. Does the pass thru sensor operate correctly? Yes Go to step 2 Go to step 3 Go to step 7 Go to step 5 Replace the pick arm rolls. Replace both rolls at the same time. Check for any obstructions that might catch the media and create a paper jam. No Inform the customer that media loaded in Tray x does not meet media specifications. Load the media correctly. Go to step 4 Go to step 8 Go to step 6 Go to step 7 2-36 Service Manual