Brother International DreamWeaver„ VQ3000 Users Manual - English - Page 211

Troubleshooting

|

View all Brother International DreamWeaver„ VQ3000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 211 highlights

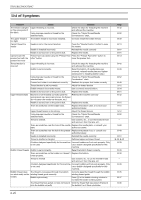

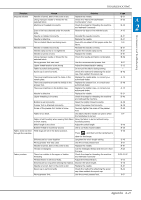

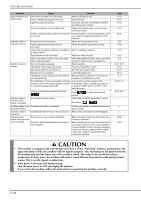

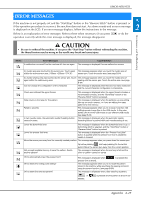

TROUBLESHOOTING Problem Skipped stitches Needle breaks Fabric does not feed through the machine Fabric puckers Cause Solution Needle is turned, bent or the point is dull. Replace the needle. Using improper needle or thread for the selected fabric. Check the "Fabric/Thread/Needle Combination" chart. Machine is threaded incorrectly. Check the steps for threading the machine and rethread it correctly. Dust or lint has collected under the needle plate. Remove the dust or lint with the brush. Needle is installed incorrectly. Reinstall the needle correctly. Needle is defective. Replace the needle. Thin or stretch fabrics are being sewn. Sew with one sheet of thin paper under the fabric. Needle is installed incorrectly. Reinstall the needle correctly. Needle clamp screw is not tightened. Tighten the needle clamp screw. Needle is turned or bent. Replace the needle. Using improper needle or thread for the selected fabric. Check the needle and fabric combination. Wrong presser foot was used. Use the recommended presser foot. Upper thread tension is too strong. Adjust the thread tension setting. Fabric is pulled during sewing. Do not pull the fabric during sewing. Spool cap is set incorrectly. Check the method for attaching the spool cap, then reattach the spool cap. There are scratches around the holes in the needle plate. Replace the needle plate, or consult your authorized dealer. There are scratches around the hole(s) in the Replace the presser foot, or consult your presser foot. authorized dealer. There are scratches on the bobbin case. Replace the bobbin case, or consult your authorized dealer. Needle is defective. Replace the needle. Upper threading is incorrect. Check the steps for threading the machine and rethread the machine. Bobbin is set incorrectly. Reset the bobbin thread correctly. Presser foot is attached incorrectly. Attach the presser foot correctly. Screw of the presser foot holder is loose. Securely tighten the screw of the presser foot. Fabric is too thick. Use fabric that the needle can pierce when the handwheel is turned. Fabric is fed forcefully when sewing thick fabric Allow the fabric to be fed without being or thick seams. forcefully pushed. Stitch length is too short. Adjust the stitch length. Bobbin thread is incorrectly wound. Use a correctly wound bobbin. Feed dogs are set in the down position. Press , and then turn the handwheel to raise the feed dogs. Stitches are too close together. Lengthen the stitch length setting. Wrong presser foot was used. Use the correct presser foot. Needle is turned, bent or the point is dull. Replace the needle. Thread is entangled. Cut the entangled thread and remove it from the race. There is a mistake in the upper or bobbin threading. Check the steps for threading the machine and rethread it correctly. Thread tension is set incorrectly. Adjust the thread tension. Stitches are too long when sewing thin fabrics. Shorten the stitch length. Needle is turned, bent or the point is dull. Replace the needle. Spool cap is set incorrectly. Check the method for attaching the spool cap, then reattach the spool cap. Wrong presser foot. Use the correct presser foot. Page B-51 B-52 B-42 A-15 B-51 B-51 S-9 B-51 B-51 B-51 B-52 S-67 S-12 - B-42 A-15 B-49 A-15 B-51 B-42 B-39 B-49 B-49 S-7 S-10 B-34 S-40 S-10 S-67 B-51 A-23 B-39, B-42 S-12 S-10 B-51 B-42 S-67 Maintenance and Troubleshooting A 2 Appendix A-27