Kyocera KM-1820 1820 Operation Guide (Advanced Edition) - Page 128

Postcards, Envelopes, ADVANCED OPERATION GUIDE, Appendix-7, Paper Grain - jam 40

|

View all Kyocera KM-1820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 128 highlights

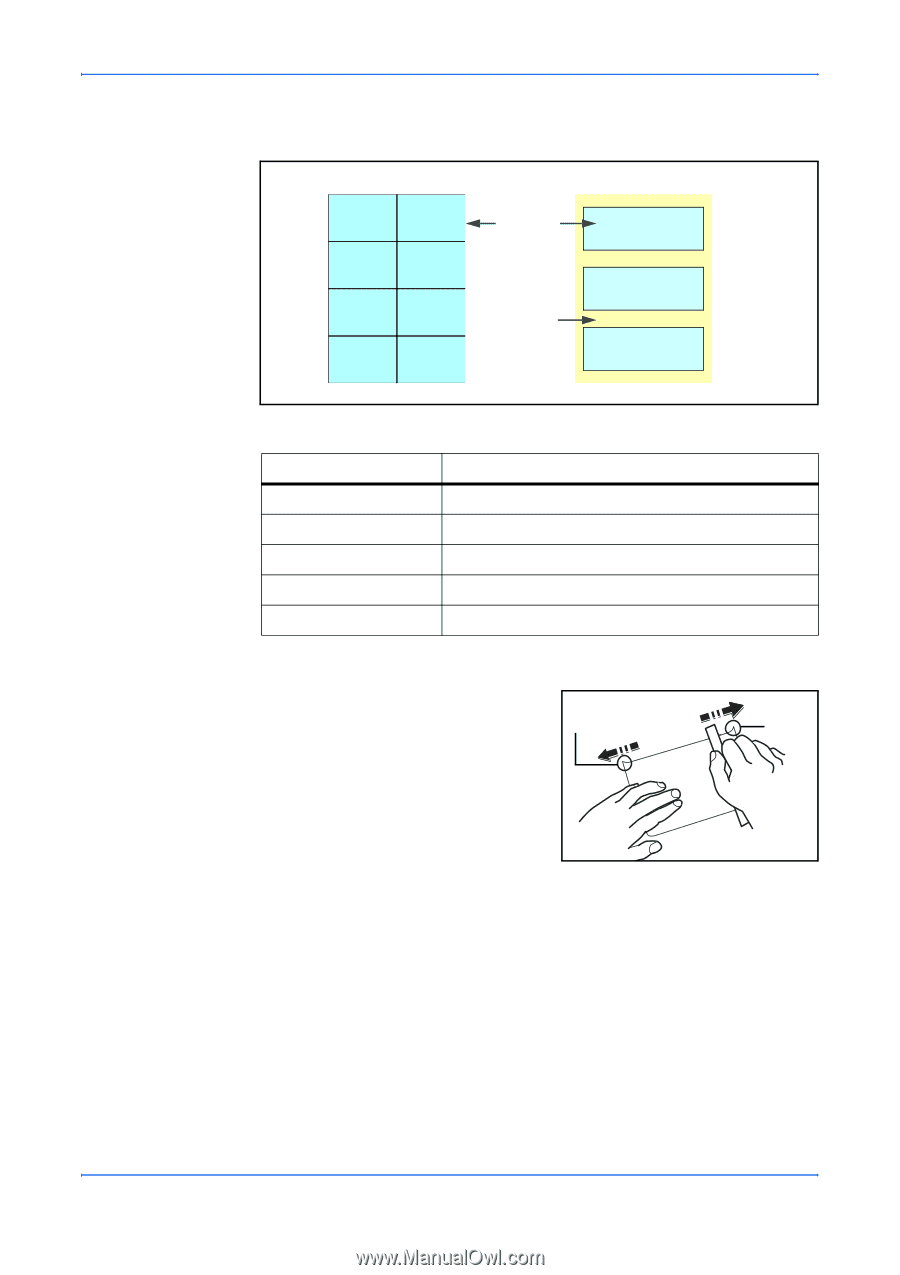

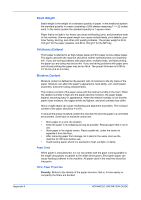

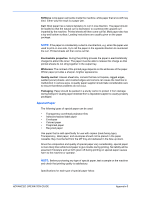

Some label paper is manufactured with an extra margin of top sheet around the edge. Do not remove the extra top sheet from the carrier sheet until after printing is completed. Acceptable Unacceptable Top sheet Carrier sheet The table below lists the specifications for adhesive label paper. Item Weight of top sheet Composite weight Thickness of top sheet Composite thickness Moisture content Specification 44 to 74 g/m² (12 to 20 lb/ream) 104 to 151 g/m² (28 to 40 lb/ream) 0.086 to 0.107 mm (3.9 to 4.2 mils) 0.115 to 0.145 mm (4.5 to 5.7 mils) 4 to 6% (composite) Postcards Fan the stack of postcards and align the edges before loading them in the MP tray. Check that the postcards you are going to set are not curled. Feeding curled postcards may cause paper jams. Rough Edge Some postcards have rough edges on the back (those are created when the paper is cut). In this case, put the postcards on a flat place and rub the edges with, for example, a ruler to smooth them. Rough Edge Envelopes The machine can print on envelopes using paper with a basis weight of 60 to 79 g/ m² (16 to 21 lb/ream). Envelopes must be manually fed. An envelope is a more complex object than a single sheet of paper. For this reason, it may not be possible to obtain consistent printing quality over the entire envelope surface. Many envelopes have a diagonal grain orientation. (Refer to Paper Grain on page Appendix-4.) This orientation is more likely to wrinkle and crease on its way through the machine. Before purchasing envelopes for use with the machine, test a sample to verify the envelope's suitability. ADVANCED OPERATION GUIDE Appendix-7