HP LaserJet M1005 Service Manual - Page 146

Repetitive image defect ruler, Print cartridge 37.7 mm 1.48 inches°

|

View all HP LaserJet M1005 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 146 highlights

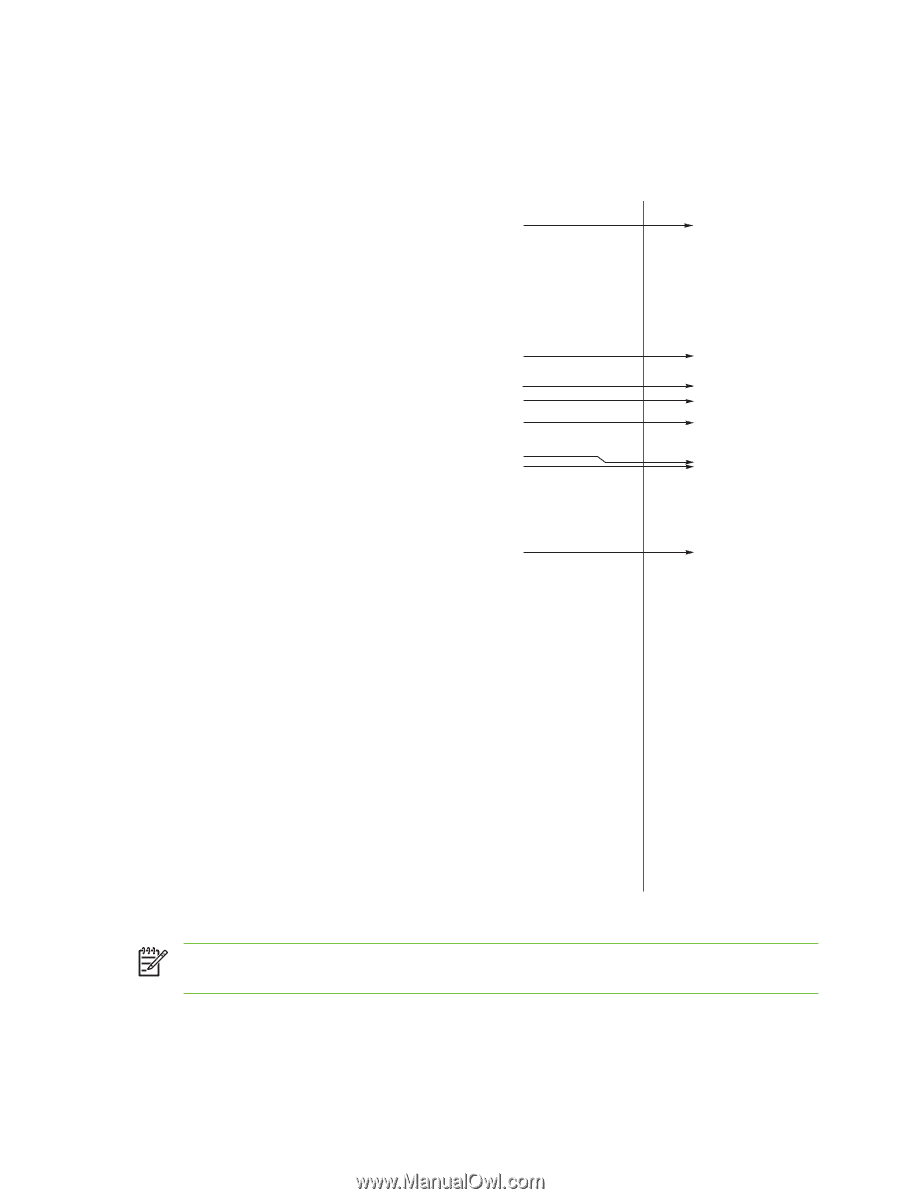

Repetitive image defect ruler Use the repetitive image-defect ruler to help solve image quality problems. Place the top line on the ruler next to the first occurrence of the defect on the page. Find the mark that points to the next instance of the defect to identify the component that is causing the defect. First occurrence of print defect (0.00 inches) Print cartridge 30.8 mm (1.21 inches) Print cartridge 37.7 mm (1.48 inches) Fuser (Fixing assembly) 41.0 mm (1.61 inches) Transfer roller 46.3 mm (1.82 inches) Paper pick-up assembly 55.2 mm (2.17 inches) Fuser (Fixing assembly) 56.5 mm (2.22 inches) Print cartridge 76.3 mm (3.00 inches) Figure 7-1 Repetitive image defect ruler NOTE The repetitive image defect ruler is for reference only and may not display or print to exact scale. Use a measuring device to determine the spacing between repeating image defects. 130 Chapter 7 Troubleshooting ENWW