Intel 640 User Guide - Page 43

Recommended Test Sequence, 2.1.2.2, Post-Test Pass Criteria

|

UPC - 683728178901

View all Intel 640 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

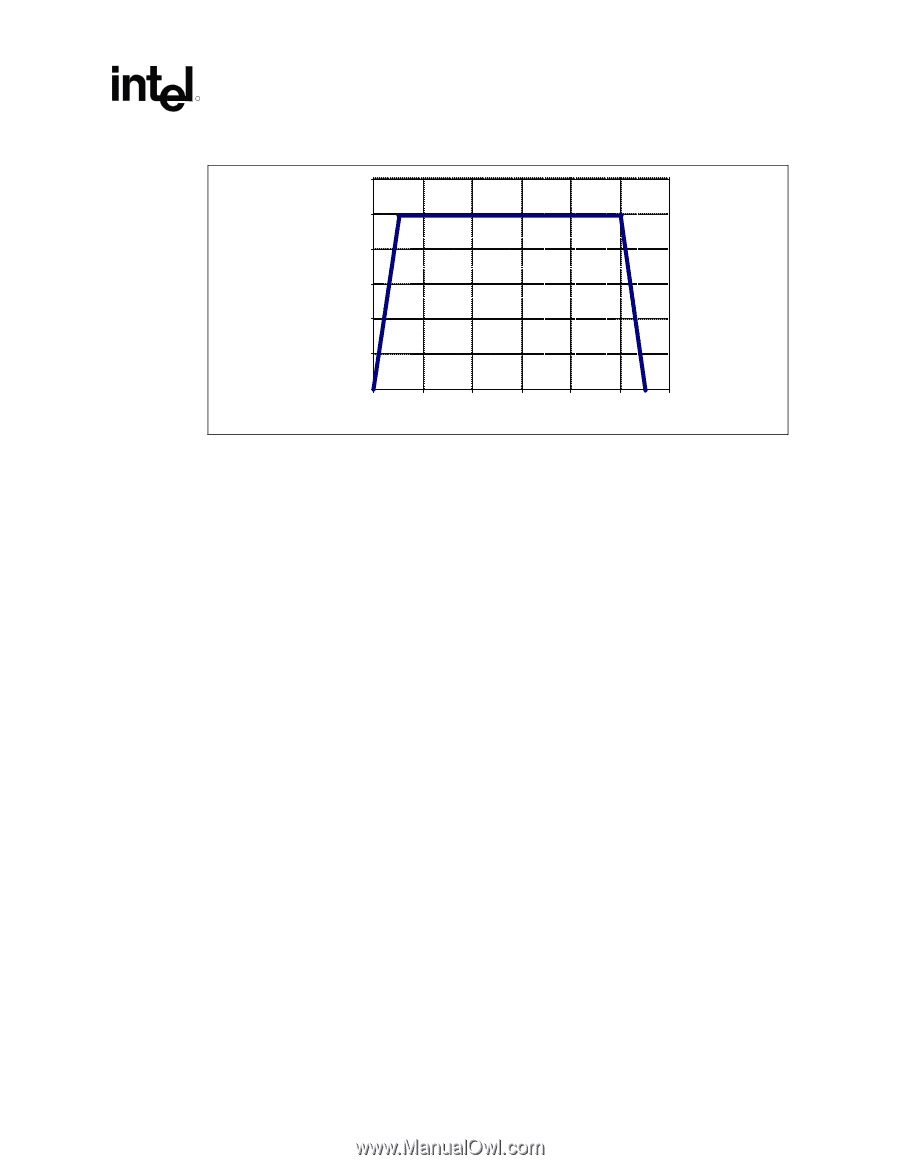

Intel® Thermal/Mechanical Reference Design Information R Figure 9. Shock Acceleration Curve 60 A c c 50 e l 40 e r 30 a t 20 i o n 10 (g) 0 0 2 4 6 8 10 12 Time (m illiseconds) 5.2.1.2.1 5.2.1.2.2 Recommended Test Sequence Each test sequence should start with components (i.e., motherboard, heatsink assembly, etc.) that have not been previously submitted to any reliability testing. The test sequence should always start with a visual inspection after assembly, and BIOS/Processor/Memory test (refer to Section 5.2.3). Prior to the mechanical shock and vibration stress test, the units under test should be preconditioned for 72 hours at 45 ºC. The purpose is to account for load relaxation during burn-in stage. The stress test should be followed by a visual inspection and then BIOS/Processor/Memory test. Post-Test Pass Criteria The post-test pass criteria are: 1. No significant physical damage to the heatsink attach mechanism (including such items as clip and motherboard fasteners). 2. Heatsink must remain attached to the motherboard. 3. Heatsink remains seated and its bottom remains mated flatly against IHS surface. No visible gap between the heatsink base and processor IHS. No visible tilt of the heatsink with respect to its attach mechanism. 4. No signs of physical damage on motherboard surface due to impact of heatsink or heatsink attach mechanism. 5. No visible physical damage to the processor package. 6. Successful BIOS/Processor/memory post-test of samples. 7. Thermal compliance testing to demonstrate that the case temperature specification can be met. Thermal/Mechanical Design Guide 43