Epson C7500G Technical Reference Guide - Page 125

e label/ Glossy label, GS1 DataBar Truncated

|

View all Epson C7500G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 125 highlights

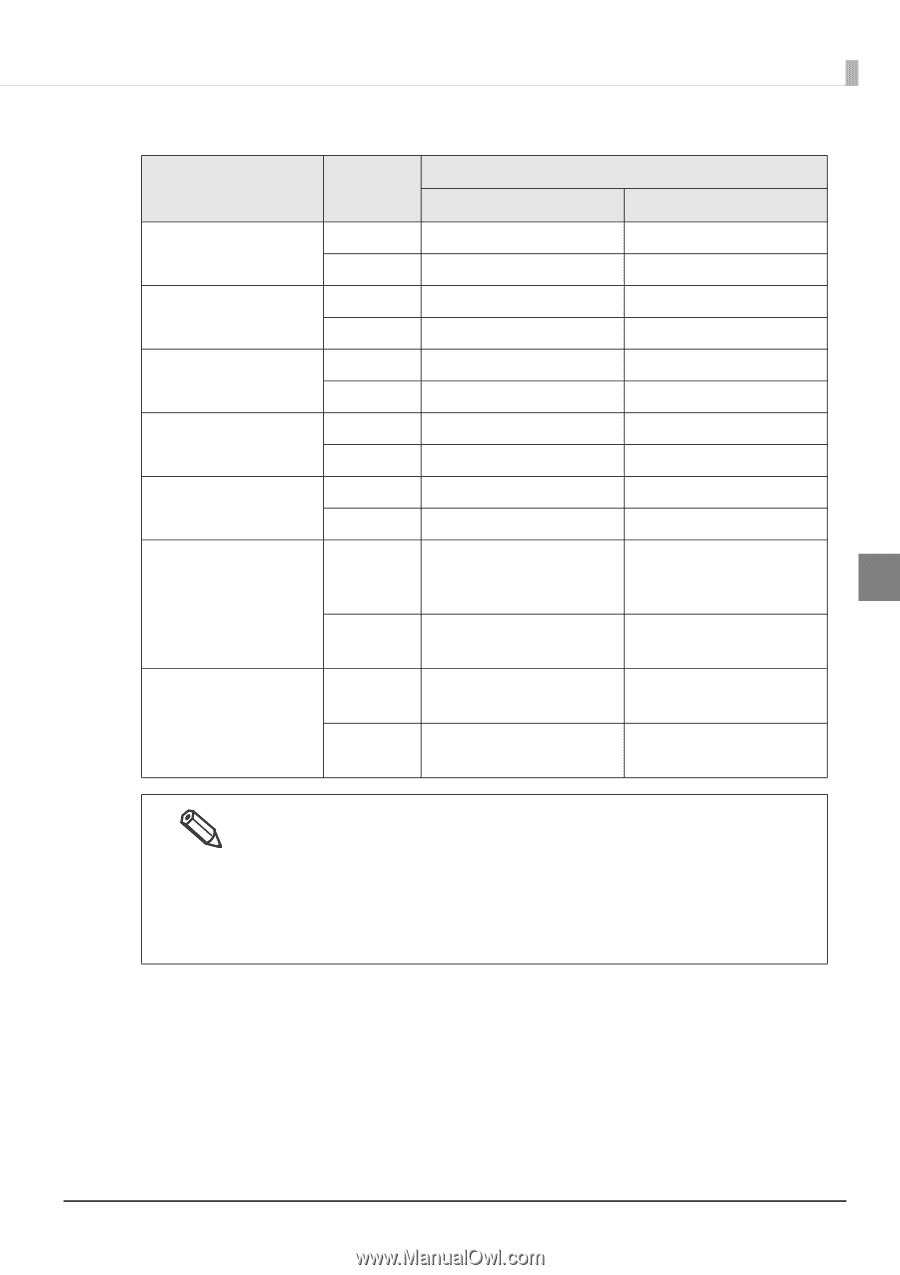

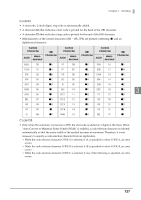

Chapter 3 Handling • Matte label/ Glossy label Barcode type Printing direction Minimum Module [by 600 dpi] ANSI Grade C or higher ANSI Grade B or higher Fence 5 6 Code39 Ladder 5 6 Fence 5 6 Codabar(NW7) Ladder 5 6 Fence 5 6 Code93 Ladder 5 6 Code128 Fence 5 6 GS1-128 Ladder 5 6 Fence 6 7 ITF Ladder 6 7 GS1 DataBar Omnidirectional Fence 6 GS1 DataBar Truncated 6 3 GS1 DataBar Limited Ladder 6 6 GS1 DataBar Expanded UPC-A Fence 7 7 UPC-E JAN13(EAN) Ladder 7 7 JAN8(EAN) The recognition rate for the barcode varies depending on the media type, barcode reader's performance and so on. The barcode rank may decline due to missing dots or curving on the ink drops, making the barcode unreadable by the barcode reader. Thus, we recommend that you try printing HRI characters and so on. Ink may penetrate the paper due to its characteristics, and bars of printed barcodes tend to become thicker. This tendency is more prominent with some papers. To maintain the barcode recognition rate, use methods such as reducing the data in a bar by 2 pixels and increasing the blank space by 2 pixels (Bar width adjustment). 125