Epson C7500G Technical Reference Guide - Page 22

Nozzle Verification Technology

|

View all Epson C7500G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

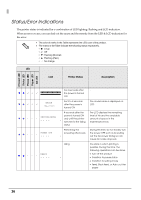

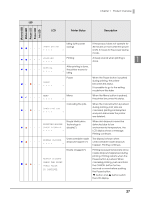

Nozzle Verification Technology This product has an "Nozzle Verification Technology" that detects missing dots. You can select the "Nozzle Verification Technology Enable / Disable", "Nozzle check interval" and/or "Threshold of clogged nozzles", depending on level of requirement for missing dots. And when unrecoverable clogging occurs, this printer is able to carry out supplemental printing using a nearby nozzle. If you set "Enable" for the nozzle clog auto supplement system, it will be possible to remedy a marked fall in print quality and barcode quality due to an irrecoverably clogged nozzle. Setting the Nozzle Verification Technology If you set "Enable" for the Nozzle Verification Technology, in the cases described below or every time the number of printed copies in "Setting Nozzle check interval" has been reached, an auto nozzle check will be performed. • Starting a printing job or per printed sheets specified in the interval of Nozzle check interval • Power is turned ON • The maintenance box cover is closed • The roll paper cover or paper set cover is closed after a paper jam. If the number of nozzle dropouts that is detected exceeds the "Threshold of clogged nozzles" that you have set, auto head cleaning will be executed to eliminate dot dropout. Perform a nozzle check even after auto cleaning, and if the number of dropouts does not fall below the set "Threshold of clogged nozzles", perform auto cleaning again. CAUTION This Nozzle Verification Technology cannot detect 100% of dot missing cases. It cannot detect 100% of missing dots and ink droplet curvature. Print head maintenance is executed for all heads simultaneously. It is not executed only for the heads and ink in which nozzle clogging was detected. The Nozzle Verification Technology uses a small amount of ink. After detecting a missing dot, cleaning is performed automatically and ink is also used in the cleaning. 22