Epson C7500G Technical Reference Guide - Page 24

Dot substitution

|

View all Epson C7500G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

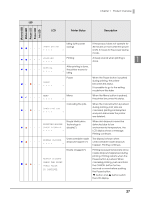

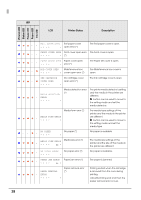

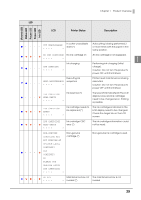

Dot substitution The dot substitution is a function that performs complementary printing using the nearby nozzles when nozzles are clogged. The maximum number of clogged nozzles that can be automatically supplemented is 16. However, supplementation cannot be performed adequately in the case of clogging of an adjacent nozzle. Note that in the case of more than 16 clogged nozzles, supplementation for 16 nozzles will be implemented. After that, printing can continue. This function does not become enabled even when setting the dot substitution to enable if the Nozzle Verification Technology is disabled. This function does not completely remedy falls in print quality, barcode quality and so forth. This system carries out supplementation according to nozzle dropout information known at the start of printing, and therefore is not able to supplement nozzle dropout that occurs during printing. Settings It can be set from the setting menu of this product and PrinterSetting. The factory setting is "On". See "Setting panel switch" on page 82 or "PrinterSetting" on page 89 24