Kyocera FS-9120DN FS-9120DN/9520DN Operation Guide Rev-2 - Page 17

Special Paper, 2.1 Transparency (Overhead Projection Film), 2.2 Adhesive-Backed Labels - drum

|

View all Kyocera FS-9120DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

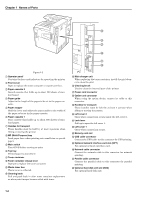

Chapter 2 Handling Paper 2. Special Paper This section explains printing on special paper. The page printer can use the following types of special paper. In this case, set the media type according to the table below. Paper type to be used Colored paper Preprinted paper Overhead projector transparencies Postcards Envelopes Label Table 2-4 Media type to be selected Color Preprinted Transparency Cardstock Envelope Labels When using the above types of paper, be sure to use products that are specified for use with photocopiers and/or page printers. Feed paper other than colored paper or preprinted paper from the MP (multi-purpose) tray. Use paper that is sold specifically for use with copiers (heat-fusing type). Label paper and envelopes should not be placed in the cassette. Since the composition and quality of special paper vary considerably, special paper is more likely than white bond paper to give trouble during printing. No liability will be assumed if moisture, etc., given off in printing on special paper causes harm to the machine or operator. NOTE Before purchasing any type of special paper, test a sample on the printer and check that print quality is satisfactory. Specifications for each type of special paper are given below. 2.1 Transparency (Overhead Projection Film) Transparency must be able to withstand the heat of fusing during the printing process. It should satisfy the conditions given in the table below. Item Tolerance of heat Thickness Material Dimensional accuracy Squareness of corners Table 2-5 Specification Must tolerate at least 190 °C (374 °F) 0.100 to 0.110 mm (3.9 to 4.3 mils) Polyester ±0.7 mm (±0.0276 inches.) 90° ± 0.2° If transparency jams frequently, pull the top of the sheet very gently as it leaves the printer. 2-4 2.2 Adhesive-Backed Labels The basic rule for printing on adhesive labels is that the adhesive must never come into contact with any part of the printer. Adhesive paper sticking to the drum or rollers will damage the printer. Label paper must be manually fed. Label paper has a structure comprised of three layers, as shown in the figure below. The top sheet is printed on. The adhesive layer consists of pressure-sensitive adhesives. The carrier sheet (also called the linear or backing sheet) holds the labels until use. Due to the complexity of its composition, adhesive-backed label paper is particularly likely to give trouble in printing. Top sheet (White bond paper) Adhesive Carrier sheet Figure 2-2 Adhesive label paper must be entirely covered by its top sheet, with no spaces between the individual labels. Labels with spaces in between are apt to peel off, causing serious paper jam problems. Some label paper is manufactured with an extra margin of top sheet around the edge. Do not remove the extra top sheet from the carrier sheet until after printing is finished. Acceptable Top sheet Unacceptable Carrier sheet Figure 2-3 The table below lists the specifications for adhesive label paper. Item Weight of top sheet Composite weight Thickness of top sheet Composite thickness Moisture content Table 2-6 Specification 44 to 74 g/m2 (12 to 20 lb/ream) 104 to 151 g/m2 (28 to 40 lb/ream) 0.086 to 0.107 mm (3.9 to 4.2 mils) 0.115 to 0.145 mm (4.5 to 5.7 mils) 4 to 6 % (composite) Envelopes The printer can print on envelopes using paper with a basis weight of 60 to 79 g/m2 (16 to 21 lb/ream). Envelopes must be manually fed. An envelope is a more complex object than a single sheet of paper. For this reason, it may not be possible to obtain consistent print quality over the entire envelope surface.