HP Designjet 250c Service Manual - Page 150

Plain + Error + Ready, Load Media + Error + Film, Error + Film + Ready, If the problem remains

|

View all HP Designjet 250c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 150 highlights

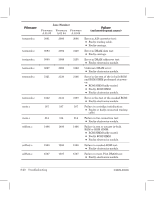

Steady 136 Steady 139 Plain + Error + Ready: RSĆ232ĆC data overflow. Data byte was not read before another was entered into the UART. Possible causes are: D Incorrect configuration in communications speed/protocol. D Incorrect communications cable. D Error in host computer. D Faulty electronics module. Plain + Error + Roll: Processor fault. D Turn the plotter off, and then on again to see if the problem disappears. D If the problem remains, consult recent service notes for a possible solution. D If no service note deals with this error, report the problem to your HP Response Center. Note conditions and actions before error occurred. Include setup sheet and service configuration plot in report. Steady 234 Steady 238 Steady 346 Load Media + Error + Film: Servo error in the YĆaxis (carriage axis). Try one or more of the following: D Clear any binding due to a media jam. D Turn the plotter off. Manually move the carriage along the carriage axis. Check for any areas where the carriage may be binding. D Ensure that the belt and belt pulley are in correct working order. Remove dirt from the pulley that could cause the belt to slip. D Perform the carriageĆaxis test and the servo/encoder test to check for problems with the carriage motor, encoder strip, and electronics module. D Remove dirt from the slider rod and chassis beam. Apply oil (Anderol 4068, HP part number: 6040Ć0858) to the carriage bushings. D At high temperatures, and if the fan is not working correctly, the internal resistance of the motor driver may increase, causing a decrease in the voltage between the motor contacts, and a shutdown of the motor. D Ensure that the encoder strip is not inverted, damaged or absent. D Reconnect or replace the trailing cable. D Replace the carriage. For more precise troubleshooting ' page 8Ć23, w System Errors. Load Media + Error + Normal: Error in XĆaxis calibration. D Is XĆaxis calibration done? D Did you load media in correct orientation? D Are the marks visible on the plot? If not, check cartridges. D Are cartridges correctly aligned? If so, the problem may be in the electronics module, media motor or driveĆroller gear; if alignment is incorrect, the problem may be in the carriage. Error + Film + Ready: Failure of RSĆ232ĆC loopback test. Ensure the loopback connector is the appropriate one. If the problem remains, replace the electronics module. 8Ć16 Troubleshooting C4699Ć90000