HP Designjet 250c Service Manual - Page 172

Bench Run, CarriageĆAxis Test, Thistests the operation of the carriage motor, belt, tensioner

|

View all HP Designjet 250c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 172 highlights

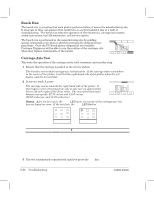

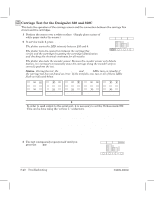

Bench Run The bench run is a routine that each plotter performs before it leaves the manufacturing site. It attempts to filter out plotters that could have an early breakdown due to a fault in manufacturing. The bench run tests the operation of the electronics, carriageĆaxis system, mediaĆaxis system, bailĆlift mechanism, and service station. The bench run is performed at the manufacturing site by sending Bench Run special commands to the plotter and then pressing the indicated frontĆ panel keys. Once the PCĆbased plotter diagnostics are available, Customer Engineers will be able to run the routine at the customer site when they replace critical parts of the plotter. ALT CarriageĆAxis Test This tests the operation of the carriage motor, belt, tensioner, and encoder strip. 1 Ensure that the carriage is parked in the service station. The test does not include carriageĆaxis initialization. If the carriage starts somewhere in the center of the plotter, it will hit the rightĆhand side of the plotter when the test begins, and the test will fail. Carriage-Axis 2 In service mode 1, press Carriage-Axis Test. Test The carriage moves towards the rightĆhand side of the plotter. It then begins cycles of moving from side to side over an approximate 50Ćcm (20Ćinch) span of the drive roller. The movement alternates between two speeds: 67.73 cm/sec and 33.87 cm/sec (26.67 inches/sec and 13.33 inches/sec). Status. After the first cycle, the Paper LED turns on (steady) if the carriageĆaxis test has not found an error. If the test fails, the Paper LED flashes. OK Failed Output to the Serial Port (Viewing Output ' 8-36) Error code: If an error has occurred, this code specifies more precisely what has gone wrong during the test. Include this information in the report to your HP Response Center, if the problem cannot be fixed. Speed: Speed for each carriage cycle. Maximum PWM: For each carriage cycle, the maximum PWM once the carriage achieves a constant speed. A typical carriage-axis PWM is 75. The maximum allowed is 102. 3 The test continuously repeats itself until you press the Shift key. 8Ć38 Troubleshooting C4699Ć90000