HP Designjet 250c Service Manual - Page 165

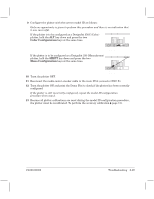

If the carriage moves over the engaging lever, condition

|

View all HP Designjet 250c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 165 highlights

Carriage cannot park in service station. Mispositioned trailing cable: The trailing cable may be preventing the carriage from reaching the leftĆhand stop. Make sure that the trailing cable is positioned under the plastic tabs at the back of the carriage cover, and not above them. Drive belts wear out prematurely. Diazo copiers: The belt may wear prematurely if the plotter is placed near a diazo copier that uses ammonia to produce blueĆline copies. The material used in the belt is very reactive to ammonia vapor. The vapor is very corrosive and can damage other parts as well. Move the plotters away from such copiers. Storing: Keep new belts in their bags with dissicant until you need to install them. This is to avoid incorrect swelling. Noisy carriage movement. Dirty carriage wheel: Remove aluminum or dust particles from the wheel at the back of the carriage, and from the slider path along which the wheel moves. Bail mechanism fails. Wearing of parts: The cam gear and engaging gear may not make correct contact with the left driveĆroller gear even though the carriage is actuating the engaging lever. This can happen due to excessive wearing of parts. Another problem may be that the bail cable has broken. Carriage motor control: The carriage may not properly locate the engagement lever, preventing the gears from engaging. Any problems with the carriageĆmotor control system (for example, the encoder strip) or associated mechanics could cause this problem. Also, if the carriage cannot find the true left stop during initialization (caused by interference), the engaging lever cannot be located. Bail cam: The bail may fall from the up position. This can happen if the cam is over or underĆrotated. The notch on the cam, used to engage the left bail bracket, is not properly located for the bail up" condition, and the bail falls abruptly. Perform a bail cycle test. Adjust carriage: If the carriage moves over the engaging lever without raising it, you may need to adjust the carriage angle on the slider rod. (Details ' page 7Ć11.) However, be careful not to jeopardize the print quality, which is very sensitive to the carriage angle. Bail starwheels slip off overdrive roller wheels. Media jam. CĆclips: Ensure that the cĆclips and bushings are correctly installed on the left end of the overdrive roller, to prevent its movement from side to side. Ink spilling. Spittoon and ink separator: You need to replace these parts when they fill up with ink. (See ' chapter 4.) Static charge causing AntiĆstatic brush: If this brush (located under the entry platen) is media jams. damaged or removed, static charge can build up on the media. A charge can cause the media to stick to itself and jam the plotter. C4699Ć90000 Troubleshooting 8Ć31