HP 450c Service Manual - Page 198

Carriage Axis, Service Test

|

View all HP 450c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 198 highlights

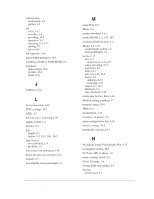

A absorption, ink, 6Ć17 AC power outlet, 8Ć3 Accuracy Calibration, 1Ć3, 5Ć2 before performing, 5Ć3 performing, 5Ć3 adjust carriage, 1Ć8 adjusting carriage, 10Ć5 CarriageĆtoĆMedia Distance, 5Ć5 align cartridges, 1Ć5 Align Media, frontĆpanel light, 3Ć3 antiĆstatic brush, 1Ć6, 10Ć2 application notes, part number, 7Ć26 area fill, blotchy, 6Ć16 automatic bail lift mechanism, 10Ć3 B Bail part number, 7Ć22 Service Test, 4Ć23 bail, 1Ć8, 10Ć3 cam, 1Ć8 lift mechanism, 10Ć3 removing, 8Ć28 number of errors, service configuration plot, 4Ć29 system, 4Ć3 testing, 4Ć4, 4Ć5, 4Ć8, 4Ć23 Bail Assembly, 8Ć7 problem, 1Ć8 Bail Cycle, Service Test, 4Ć8 Bail Mechanisms, part number, 7Ć18 Banding, test pattern, 6Ć12 baud rate, and parity, 10Ć8 bellows, primer, 10Ć6 belt, 4Ć3 error, 2Ć9, 4Ć11 moving the carriage, 10Ć4 removing, 8Ć41 Index-2 slipping, 6Ć8 swelling, 9Ć3 bench run, 4Ć18, 4Ć29 parameters, clearing, 4Ć32 BiĆTronics, interface, 10Ć8 cables, 7Ć27 black area fills, 6Ć16 number of plots, service configuration plot, 4Ć29 bleeding, 6Ć17 blooming, 6Ć17 blotchy area fills, 6Ć16 brush, antiĆstatic, 10Ć2 bushings carriage guidance, 10Ć4 friction, 6Ć8 C Calibration, Accuracy, 1Ć3 calibration, clearing parameters, 4Ć32 cam gear wearing, bail, 1Ć8 Carriage, noisy, 1Ć4 carriage, 4Ć3, 6Ć8 axis, encoder test, 4Ć5, 4Ć25 bushings, 9Ć2 distance to media adjust, 5Ć7 check, 5Ć5 drive mechanics, 10Ć4 LED, 10Ć3 motor, 4Ć3, 10Ć4 control, 1Ć8 error, 2Ć9 removing, 8Ć18 noise, 9Ć2 PCA, 10Ć4 Carriage Assembly part number, 7Ć16 problem, 1Ć4 Carriage Axis, Service Test, 4Ć10, 4Ć12 carriageĆtoĆmedia distance, 6Ć8 HP DesignJet 430, 450C and 455CA Printers