HP LaserJet M9040/M9050 Service Manual - Page 158

Pickup and feed system, Media-size detection, Multifeed prevention, Transparency media detection

|

View all HP LaserJet M9040/M9050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 158 highlights

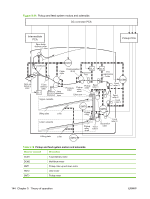

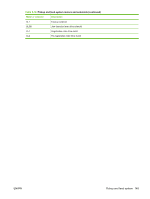

Pickup and feed system The pickup and feed system picks up single sheets from Tray 2 or Tray 3, feeds each sheet to the fuser unit, and delivers each sheet to the face-up bin or to the face-down bin. When the product is turned on, the lifter lifts the stack of media to the pickup area in preparation for printing. When the DC controller receives a print command, the pickup roller starts rotating and lowers to the paper surface. This feeds a sheet of paper to the feed rollers and to the pre-registration roller, which corrects the skew. After a short time, the sheet is fed to the photosensitive drum where the image is transferred onto the sheet. Then the sheet is fed to the fuser and delivered to a bin. Media-size detection The pickup and feed system includes a custom/standard switch and two media-size detection switches because either tray can accommodate custom media sizes. If custom/standard switch is set to standard, the DC controller determines the width and length of the media according to the size-detection switches. If the custom/standard switch is set to custom, the system requires the dimensions to be configured in the control panel. The width-detection switches also sense the presence of trays. If all of the widthdetection switches are off, the DC controller assumes that a tray is missing. Media-level detection The lifter detects the media level in the trays using a blocking plate and two sensors. The lifter position indicates the media level by shutting off the sensors. Media level is based on the approximate number of sheets in the tray: full (200 or more sheets), high (100 to 200 sheets), middle (50 to 100 sheets), or low (less than 50 sheets). Multifeed prevention The product prevents feeding of multiple sheets using torque-limited separation roller. The separation roller rotates in the opposite direction of the feed roller. The torque limiter allows the separation roller to be turned backward as the top sheet feeds into the system, but it returns additional sheets to the tray. Transparency media detection The transparency sensor detects transparency media by reading a light that shines through a prism in the media path. Paper passing through the media path blocks the light indicating that it is not a transparency. Fuser-wrapping jam detection The paper path includes a mechanism to detect jams where media wraps around fuser rollers. The DC controller sends signals to the pressure roller bias generation circuit, which applies the same bias values to the pressure roller and to the wrapping jam detection circuit. The jam-detection lever solenoid contacts the pressure roller to monitor its bias value. The wrapping jam detection circuit compares the original bias value to the bias value monitored on the pressure roller. If the values differ, the circuit signals the DC controller that a wrapping jam has occurred and to stop the printing operation. 140 Chapter 5 Theory of operation ENWW