Lexmark C540 Service Manual - Page 126

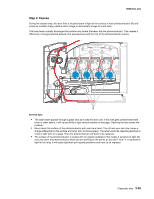

Step 3: Develop

|

View all Lexmark C540 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 126 highlights

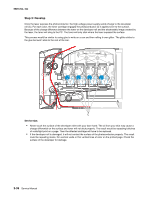

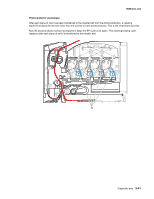

5025-2xx, 4xx Step 3: Develop Once the laser exposes the photoconductor, the high-voltage power supply sends charge to the developer roll (C). For each color, the toner cartridge engages the photoconductor so it applies toner to the surface. Because of the charge difference between the toner on the developer roll and the electrostatic image created by the laser, the toner will cling to the PC. The toner will only stick where the laser exposed the surface. This process would be similar to using glue to write on a can and then rolling it over glitter. The glitter sticks to the glue but won't stick to the rest of the can. Service tips: • Never touch the surface of the developer roller with your bare hand. The oil from your skin may cause a charge differential on the surface and toner will not stick properly. The result would be repeating blotches of voids/light print on a page. Then the affected cartridge will have to be replaced. • If the developer roll is damaged, it will not contact the surface of the photoconductor properly. The result could be repeating marks, thin vertical voids or thin vertical lines of color on the printed page. Check the surface of the developer for damage. 3-36 Service Manual