Lexmark C540 Service Manual - Page 134

Duplex process, As the media reaches the gate aligner, a sensor S1 is triggered

|

View all Lexmark C540 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 134 highlights

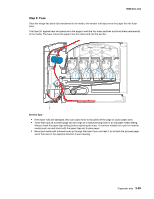

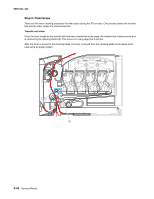

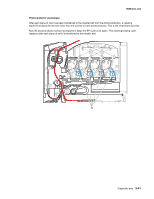

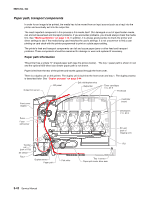

5025-2xx, 4xx Duplex process The duplex paper path is a secondary paper path in the front cover and the 250-sheet paper tray to print on the second side of a sheet of paper. After the first side of the media is printed and the trailing edge of the paper clears the fuser exit sensor, the fuser motor reverses. The reversed motor pulls the media into the duplex paper path. In addition to the fuser motor reversing, the pick motor also reverses. The pick motor drives the duplex aligner rolls (A) which push the media down to the bottom turnaround in the paper tray and gate aligner (B). Note: While the sheet is being transported through the front door and paper tray, it is the only piece of media being processed by the print engine. A user should not attempt to insert a piece of media into the manual paper feed while a duplex job is being processed. This would invoke a jam error. When the trailing edge of the media clears the fuser, the fuser engine rotates forward to prepare the fuser for the page traveling through the duplex unit. As the media reaches the gate aligner, a sensor (S1) is triggered, indicating the presence of the leading edge. When the S1 sensor is triggered, the paper continues to the S2 sensor (S2). When the S2 signal is detected, the speed of the pick motor is adjusted to accommodate the speed of the transfer belt, ensuring the proper registration of the image on the media. The paper travels to the ITU (C), and the second image is transferred to the reverse side of the media. Once the image is transferred, the media travels to the fuser (D), the fuser exit rolls (E), and the output bin. 3-44 Service Manual