HP Latex 110 Users Guide - Page 72

Avoiding substrate jams while printing

|

View all HP Latex 110 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 72 highlights

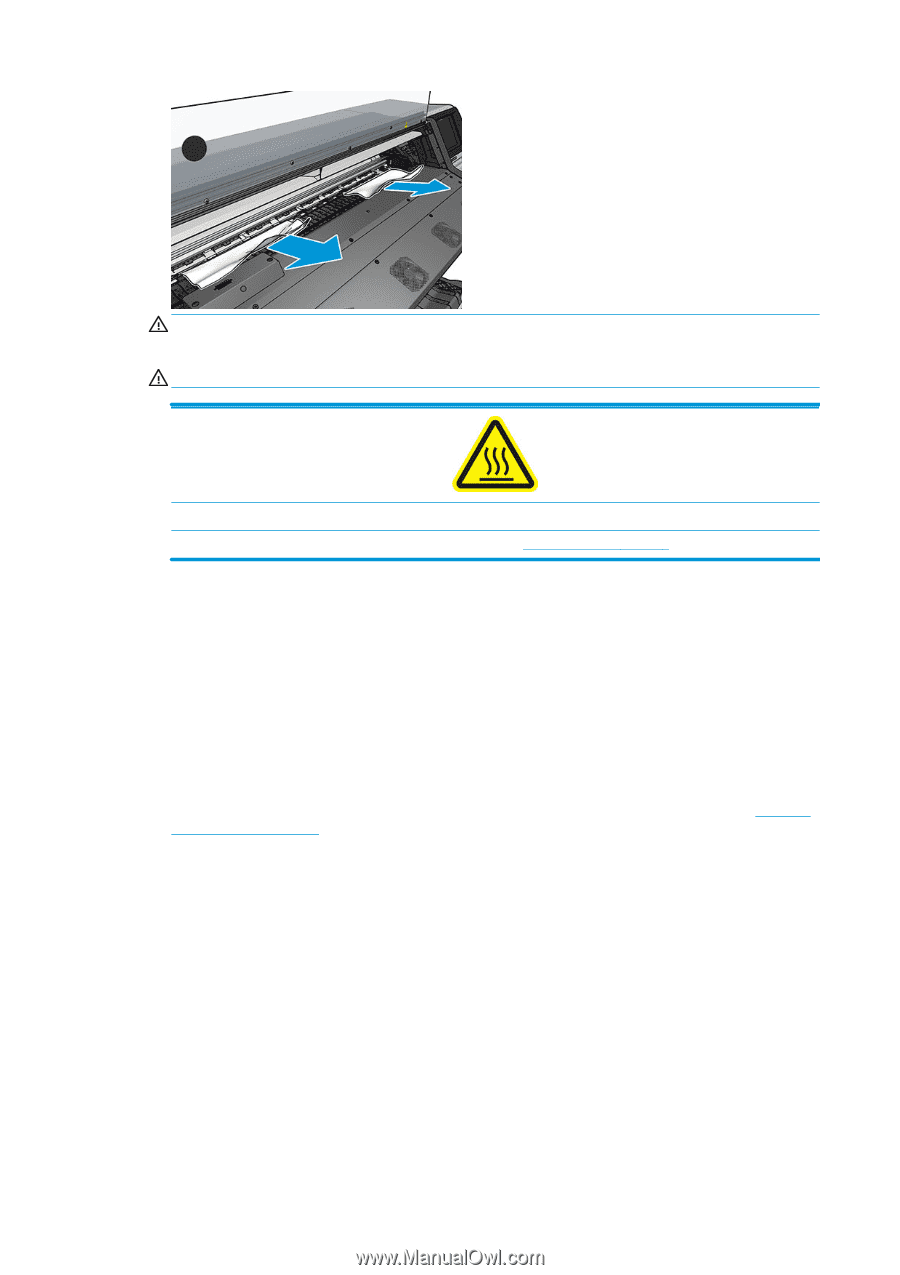

CAUTION: Try to avoid pulling the substrate out through the input path, because this reverses the normal direction of movement, and could damage printer parts. WARNING! Do not touch the printer's curing enclosure, which could be hot. Risk of burns For more safety information, please see Safety precautions on page 3 7. Lower the substrate pinch lever. 8. Make sure that there are no pieces of substrate left in the printer. In particular, check in and under the curing module, and in the substrate path. 9. Close the window. 10. Turn on the printer. 11. Reload the roll. 12. If some substrate continues to cause an obstruction within the printer, it can often be cleared by loading a rigid substrate type into the printer. 13. If you find that you have print-quality problems after a jam, try realigning the printheads. See Align the printheads on page 106. Avoiding substrate jams while printing Substrate jams may be caused by loading the substrate with too much skew: do not ignore the warning message that appears during the loading procedure in this case. They may also be caused by not enough vacuum suction in the printing zone. If you decide to increase the suction, do not exceed the following limits: 20 mmH2O for banners, 35 mmH2O for vinyl, and 50 mmH2O for other substrate families. If you experience jams only at the beginning of a print, try the following suggestions. 66 Chapter 3 Handle the substrate and troubleshoot substrate issues ENWW