HP Latex 110 Users Guide - Page 82

Advanced settings, substratre suffers from crashes or smears

|

View all HP Latex 110 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 82 highlights

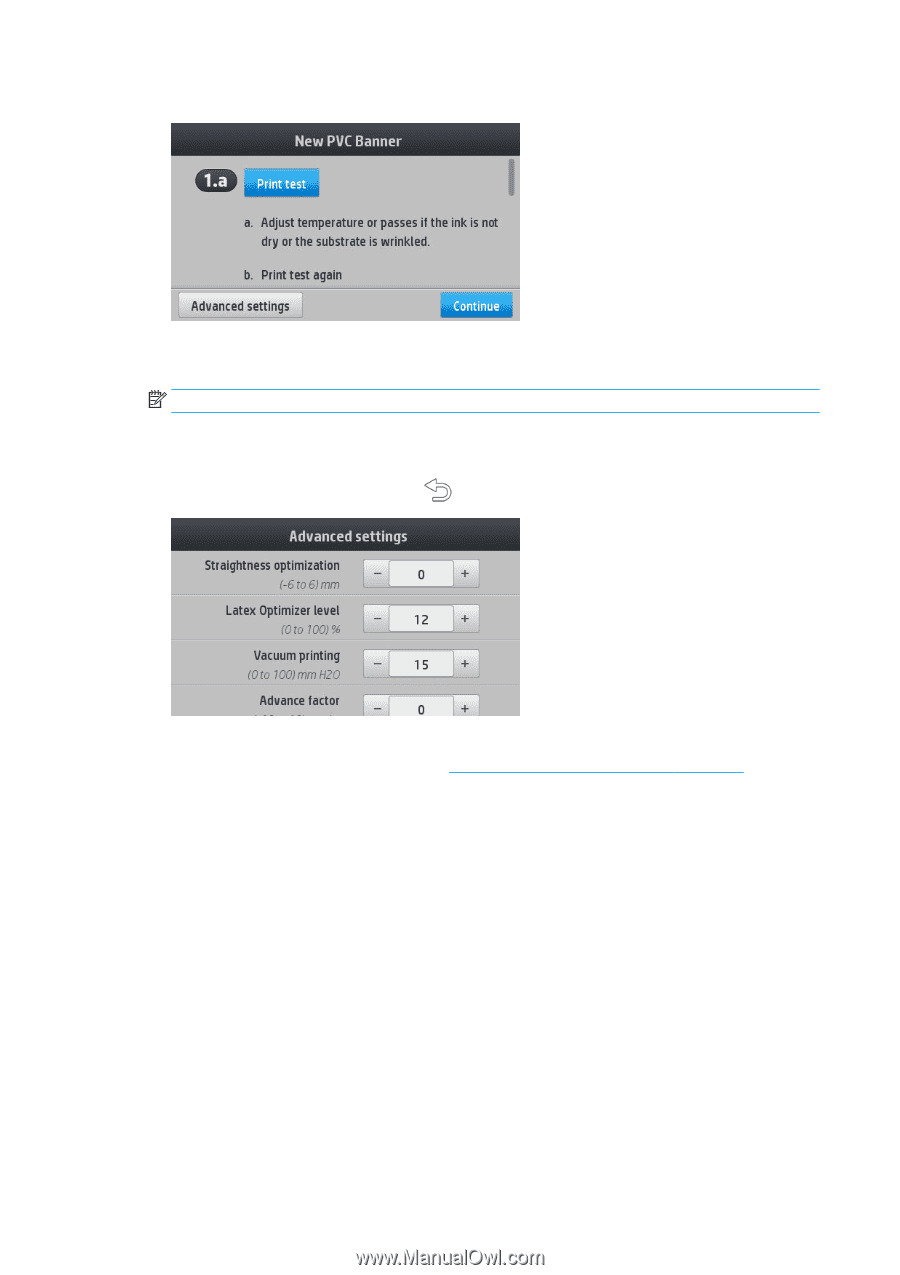

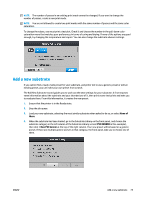

5. The following screen is displayed: 6. Press the blue button to produce the ink drying and color saturation test print; then continue adjusting the settings and printing again until you are satisfied with the result. NOTE: You can omit this step if you already know the settings that you want to use. 7. If you cannot reach a satisfactory result, you may want to press Advanced settings and try adjusting those settings, which are intended for people who understand their implications. To go back to the previous screen, press . ● Straightness or bow compensation: Allows you to compensate for barrel-shaped substrate deformation. The value represents the distance that the centre of the substrate has moved with respect to the left and right edges. See The substrate has bow deformation on page 68. ● Latex optimizer level: If you have bleed or coalescence, you can increase the optimizer level until you see a significant impact on gloss or color saturation. ● Vacuum printing: Sets the vacuum value in the print zone to hold the substrate flat. Increase if the substratre suffers from crashes or smears, decrease if you see banding or graininess. ● Advance factor: Allows you to increase or decrease the substrate advance in each carriage pass. ● Inter-pass delay offset: The time delay between passes to allow for smoother drying. Increase the delay if you have seen banding on your prints. ● Input tension: Substrate rewinder tension, increase in case of wrinkled substrate in the print .zone 76 Chapter 4 Substrate settings ENWW