Sharp MX-M260 MX-M260 MX-M310 Operation Manual - Page 123

Paper feeding problems

|

View all Sharp MX-M260 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 123 highlights

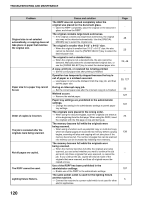

TROUBLESHOOTING AND MAINTENANCE Paper feeding problems Problem When using paper fed from the bypass tray, the copied image is skewed. Paper from the bypass tray misfeeds. Paper misfeeds. Output does not collect neatly in the output tray of the finisher. Stapled output does not collect neatly. Cause and solution The number of sheets placed on the bypass tray exceeds the maximum number. → Do not place more than the maximum number of sheets. The bypass guide is not adjusted to the size of the loaded paper. → Adjust the bypass guide to the size of the loaded paper. The paper type setting is not correct. → When using a special paper, be sure to set the correct paper type. The number of sheets placed on the bypass tray exceeds the maximum number. → Do not place more than the maximum number of sheets. The bypass guide is not adjusted to the size of the loaded paper. → Adjust the bypass guide to the size of the loaded paper. The paper is outside of the specified size and weight range. → Use copy paper within the specified range. Paper is curled or damp. → Do not use curled or crimped paper. Replace with dry copy paper. During periods when the machine is not used for a long time, remove the paper from the tray and store it in a dark place in a bag to prevent moisture absorption. Paper is not loaded properly. → Make sure the paper is properly loaded. Pieces of paper remain inside machine. → Remove all pieces of misfed paper. Sheets of paper stick together. → Fan the paper well before loading it. The paper is curled. → It may help to turn the paper over in the paper tray. The paper is curled. → It may help to turn the paper over in the paper tray. Page 16 19 21 16 19 16 142 18 127 18 - 7 121