Brother International PR1055X Operation Manual - Page 21

Adjusting the operation panel position, Preparing the thread guide assembly

|

View all Brother International PR1055X manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

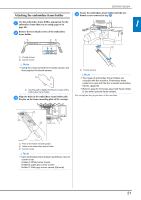

Adjusting the operation panel position Loosen 2 thumb screws to bring the operation panel a forward. GETTING READY Adjust the angle of the operation panel. d Loosen the 2 thumb screws behind the operation panel, adjust the operation panel to an easy-to-view angle, and then tighten the thumb screws. 1 1 Thumb screws Note • Using the 3 way screwdriver included, loosen and firmly tighten the thumb screws. a b 1 Use this part to tighten the upper and lower thumb screws. 2 Use this part to tighten the left and right thumb screws. Adjust the operation panel to an easy-to-operate b position, and then tighten the thumb screws. (Side view) 1 Thumb screws (Top view) Preparing the thread guide assembly CAUTION • When setting up the thread guide assembly, set it up with the needle bar 6 position selected, otherwise the machine may malfunction. (Refer to "Moving and threading a selected needle bar" on page 86 for moving the needle bar.) Loosen the two thumb screws on top of the thread a guide assembly support. Adjust the orientation of the operation panel. c Loosen the thumb screw, adjust the operation panel to an easy-to-view orientation, and then tighten the thumb screw. 1 Thumb screw 1 Turn the screw counterclockwise three or four times to loosen it. 19