Kyocera FS-9100DN FS-9100/9500 Operation Guide Rev-1.3 - Page 80

Paper Selection, 1. General Guidelines, 1.1 Paper Availability, 1.2 Paper Specifications

|

UPC - 632983001066

View all Kyocera FS-9100DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 80 highlights

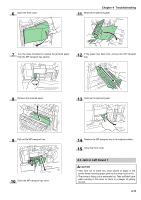

Chapter 5 Paper Selection This chapter explains the following topics: • General Guidelines • Special Paper • Paper Type 1. General Guidelines The printer is designed to print on high-quality copier bond paper (the kind used in ordinary dry copier machines), but it can also accept a variety of other types of paper within the limits specified below. NOTE The manufacturer assumes no liability for problems that occur when paper not satisfying these requirements is used. Selection of the right paper is important. Using the wrong paper can result in paper jams, misfeeding, curling, poor print quality, and paper waste, and in extreme cases can damage the printer. The guidelines given below will increase the productivity of your office by ensuring efficient, trouble-free printing and reducing wear and tear on the printer. 1.1 Paper Availability Most types of paper are compatible with a variety of machines. Paper intended for xerographic copiers can also be used with the printer. There are three general grades of paper: economy, standard, and premium. The most significant difference between grades is the ease with which they pass through the printer. This is affected by the smoothness, size, and moisture content of the paper, and the way in which the paper is cut. The higher the grade of paper you use, the less risk there will be of paper jams and other problems, and the higher the level of quality your printed output will reflect. Differences between paper from different suppliers can also affect the printer's performance. A high-quality printer cannot produce high-quality results when the wrong paper is used. Lowpriced paper is not economical in the long run if it causes printing problems. Paper in each grade is available in a range of basis weights (defined later). The traditional standard weights are 16, 20, and 28 pounds (60 to 105 g/m2). 1.2 Paper Specifications The following table summarizes the basic paper specifications. Details are given on the following pages. Item Weight Thickness Dimensional accuracy Squareness of corners Moisture content Direction of grain Pulp content Specification Cassette: 60 to 105 g/m2 (16 to 28 lb/ream) MP tray: 60 to 200 g/m2 (16 to 53 lb/ream) 0.086 to 0.110 mm (3.4 to 4.3 mils) ±0.7 mm (±0.0276 inches) 90° ±0.2° 4 to 6 % Long grain 80 % or more 1.3 Selecting the Right Paper Laser printing is a process involving laser light, electrostatic discharge, toner, and heat. In addition, as the paper passes through the printer it undergoes considerable sliding, bending, and twisting motions. A high-quality printing paper matching the printer's requirements withstands all these stresses, enabling the printer to turn out clean, crisp printed copies consistently. Remember that all paper is not the same. Some of the factors to consider when selecting paper for the printer are as follows: Condition of the Paper Avoid using paper that is bent at the edges, curled, dirty, torn, embossed, or contaminated with lint, clay, or paper shreds. Use of paper in these conditions can lead to illegible printing, misfeeding, and paper jams, and can shorten the life of the printer. In particular, avoid using paper with a surface coating or other surface treatment. The paper should have as smooth and even a surface as possible. 5-1