Kyocera FS-9100DN FS-9100/9500 Operation Guide Rev-1.3 - Page 82

Special Paper, 2.1 Transparency (Overhead Projection Film)

|

UPC - 632983001066

View all Kyocera FS-9100DN manuals

Add to My Manuals

Save this manual to your list of manuals |

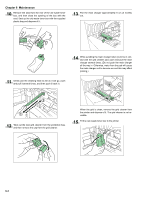

Page 82 highlights

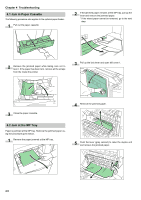

Wavy or tight edges can cause misfeeding and alignment anomalies. The moisture content of the paper should be 4 to 6%. To ensure the proper moisture content, it is important to store the paper in a controlled environment. Some tips on moisture control are: • Store paper in a cool, dry location. • Keep the paper in its wrapping as long as possible. Rewrap paper that is not in use. • Store paper in its original carton. Place a pallet, etc., under the carton to separate it from the floor. • After removing paper from storage, let it stand in the same room as the printer for 48 hours before use. • Avoid leaving paper where it is exposed to heat, sunlight, or damp. Paper Grain When paper is manufactured, it is cut into sheets with the grain running parallel to the length (long grain) or parallel to the width (short grain). Short grain paper can cause feeding problems in the printer. All paper used in the printer should be long grain. Other Paper Properties Porosity: Refers to the density of the paper structure; that is, how openly or compactly the fibers are bonded. Stiffness: Limp paper can buckle inside the printer, while paper that is too stiff may bind. Either way the result is a paper jam. Curl: Most paper has a natural tendency to curl in one direction. The paper should be loaded so that the natural curl is downward, to counteract the upward curl imparted by the printer. Printed sheets will then come out flat. Most paper also has a top and bottom surface. Loading instructions are usually given on the paper package. NOTE If the paper is considerably curled in one direction, e.g. when the paper was used to print on one side, try to roll the paper in the opposite direction to counteract the curl. Printed sheets will then come out flat. Electrostatic properties: During the printing process, the paper is electrostatically charged to attract the toner. The paper must be able to release this charge so that printed sheets do not cling together in the output tray. Whiteness: The contrast of the printed page depends on the whiteness of the paper. Whiter paper provides a sharper, brighter appearance. Quality control: Uneven sheet size, corners that are not square, ragged edges, welded (uncut) sheets, and crushed edges and corners can cause the printer to malfunction in various ways. A quality paper supplier should take considerable care to ensure that these problems do not occur. Packaging: Paper should be packed in a sturdy carton to protect it from damage during transport. Quality paper obtained from a reputable supplier is usually properly packaged. Chapter 5 Paper Selection 2. Special Paper This section explains printing on special paper. The page printer can use the following types of special paper. In this case, set the media type according to the table below. Paper type to be used Colored paper Preprinted paper Overhead projector transparencies Postcards Envelopes Label Media type to be selected Color Preprinted Transparency Cardstock Envelope Labels When using the above types of paper, be sure to use products that are specified for use with photocopiers and/or page printers. Feed paper other than colored paper or preprinted paper from the MP (multi-purpose) tray. Use paper that is sold specifically for use with copiers (heat-fusing type). Label paper and envelopes should not be placed in the cassette. Since the composition and quality of special paper vary considerably, special paper is more likely than white bond paper to give trouble during printing. No liability will be assumed if moisture, etc., given off in printing on special paper causes harm to the machine or operator. NOTE Before purchasing any type of special paper, test a sample on the printer and check that print quality is satisfactory. Specifications for each type of special paper are given below. 2.1 Transparency (Overhead Projection Film) Transparency must be able to withstand the heat of fusing during the printing process. It should satisfy the conditions given in the table below. Item Tolerance of heat Thickness Material Dimensional accuracy Squareness of corners Specification Must tolerate at least 190 °C (374 °F) 0.100 to 0.110 mm (3.9 to 4.3 mils) Polyester ±0.7 mm (±0.0276 inches.) 90° ± 0.2° If transparency jams frequently, pull the top of the sheet very gently as it leaves the printer. 5-3