Kyocera FS-9100DN FS-9100/9500 Operation Guide Rev-1.3 - Page 81

Composition, Paper Size, Smoothness, Basis Weight, Thickness Caliper, Moisture Content, MP tray

|

UPC - 632983001066

View all Kyocera FS-9100DN manuals

Add to My Manuals

Save this manual to your list of manuals |

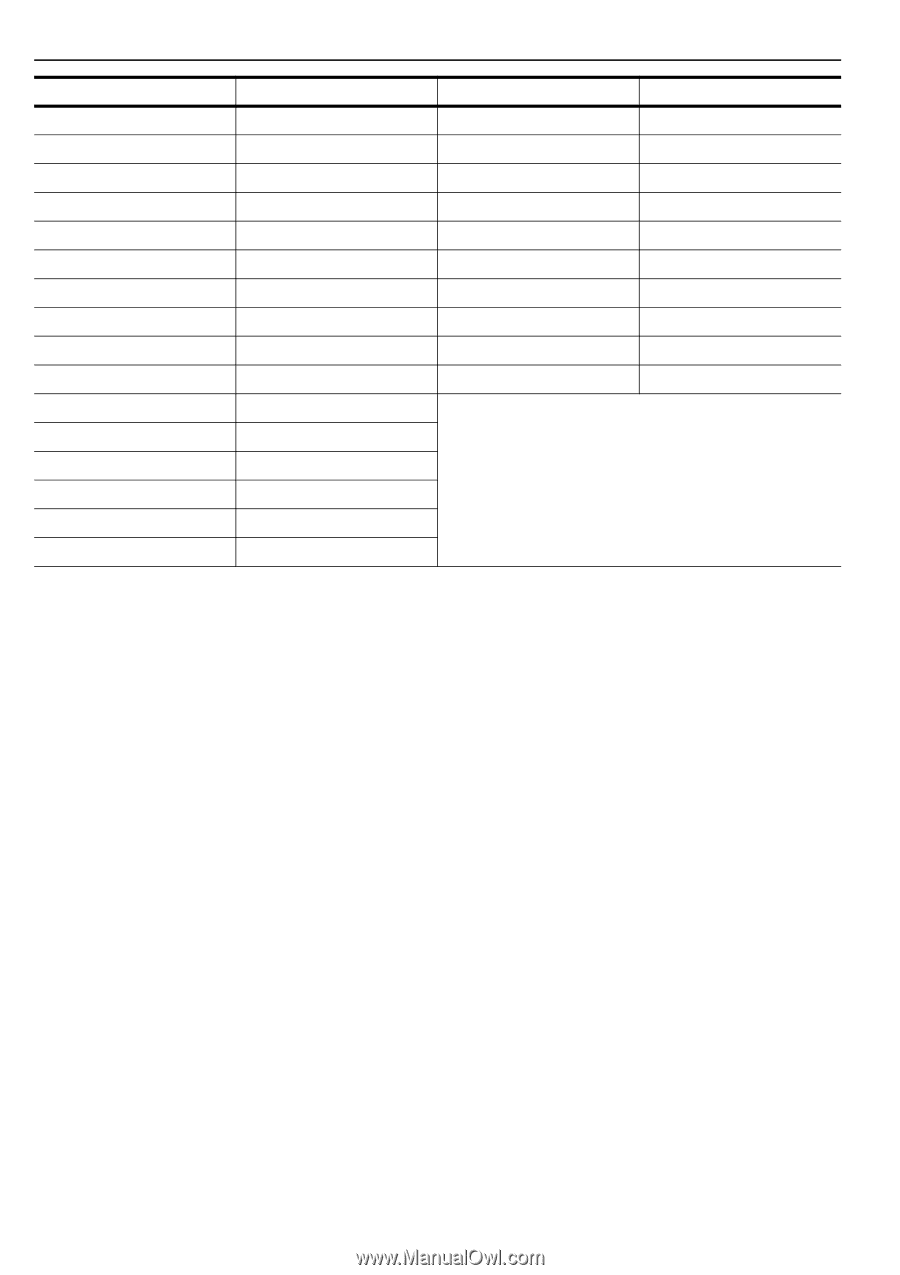

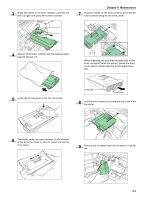

Page 81 highlights

Chapter 5 Paper Selection MP tray Monarch Business Commercial 9 Commercial 6-3/4 International DL International C5 ISO A6 JIS B6 International B5 Executive International C4 oficio II Hagaki Oufuku Hagaki Youkei 2 Youkei 4 Size 3-7/8 × 7-1/2 inches 4-1/8 × 9-1/2 inches 3-7/8 × 8-7/8 inches 3-5/8 × 6-1/2 inches 11 × 22 cm 16.2 × 22.9 cm 105 × 148 mm 128 × 182 mm 17.6 × 25 cm 7-1/4 × 10-1/2 inches 229 × 324 mm 8-1/2 × 13 inches 100 × 148 mm 148 × 200 mm 114 × 162 mm 105 × 235 mm Cassette or MP tray Size Ledger 11 × 17 inches Legal 8-1/2 × 14 inches Letter 8-1/2 × 11 inches Statement 5-1/2 × 8-1/2 inches Folio 210 × 330 mm ISO A3 297 × 420 mm ISO A4 210 × 297 mm ISO A5 148 × 210 mm JIS B4 257 × 364 mm JIS B5 182 × 257 mm Paper with other sizes (custom sizes) can also be fed from the MP tray. The minimum size paper for manual feed is 88 × 148 mm (31/2 × 5-13/16 inches), fed lengthwise. The maximum size is 297 × 450 mm (11-11/16 × 17-3/4 inches). Composition Do not use paper that has been coated or surface-treated and contains plastic or carbon. The heat of fusing can cause such paper to give off harmful fumes. Bond paper should contain at least 80 % pulp. Not more than 20 % of the total paper content should consist of cotton or other fibers. Paper Size Cassettes and an MP tray are available for the paper sizes listed in the table above. The dimensional tolerances are ±0.7 mm (±0.0276 inches) for the length and width. The angle at the corners must be 90° ±0.2°. Smoothness The paper should have a smooth, uncoated surface. Paper with a rough or sandy surface can cause voids in the printed output. Paper that is too smooth, however, can cause multiple feeding and fogging problems. (Fogging is a gray background effect.) Basis Weight Basis weight is the weight of a standard quantity of paper. In the traditional system, the standard quantity is a ream consisting of 500 sheets measuring 17 × 22 inches each. In the metric system the standard quantity is 1 square meter. Paper that is too light or too heavy can cause misfeeding, jams, and premature wear of the printer. Uneven paper weight can cause multiple feeds, print defects, poor toner fusing, blurring, and other print quality problems. The proper weight is 60 to 105 g/m2 for the paper cassette, and 60 to 200 g/m2 for the MP tray. Thickness (Caliper) Thick paper is referred to as high-caliper paper and thin paper as low-caliper paper. The paper used with the printer should be neither extremely thick nor extremely thin. If you are having problems with paper jams, multiple feeds, and faint printing, the paper you are using may be too thin. If you are having problems with paper jams and blurred printing, the paper may be too thick. The proper thickness is 0.086 to 0.110 mm (3.4 to 4.3 mils). Moisture Content Moisture content is defined as the percent ratio of moisture to the dry mass of the paper. Moisture can affect the paper's appearance, feedability, curl, electrostatic properties, and toner fusing characteristics. The moisture content of the paper varies with the relative humidity in the room. When the relative humidity is high and the paper absorbs moisture, the paper edges expand, becoming wavy in appearance. When the relative humidity is low and the paper loses moisture, the edges shrink and tighten, and print contrast may suffer. 5-2