Brother International HL 1850 Service Manual - Page 95

registration

|

UPC - 012502603900

View all Brother International HL 1850 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 95 highlights

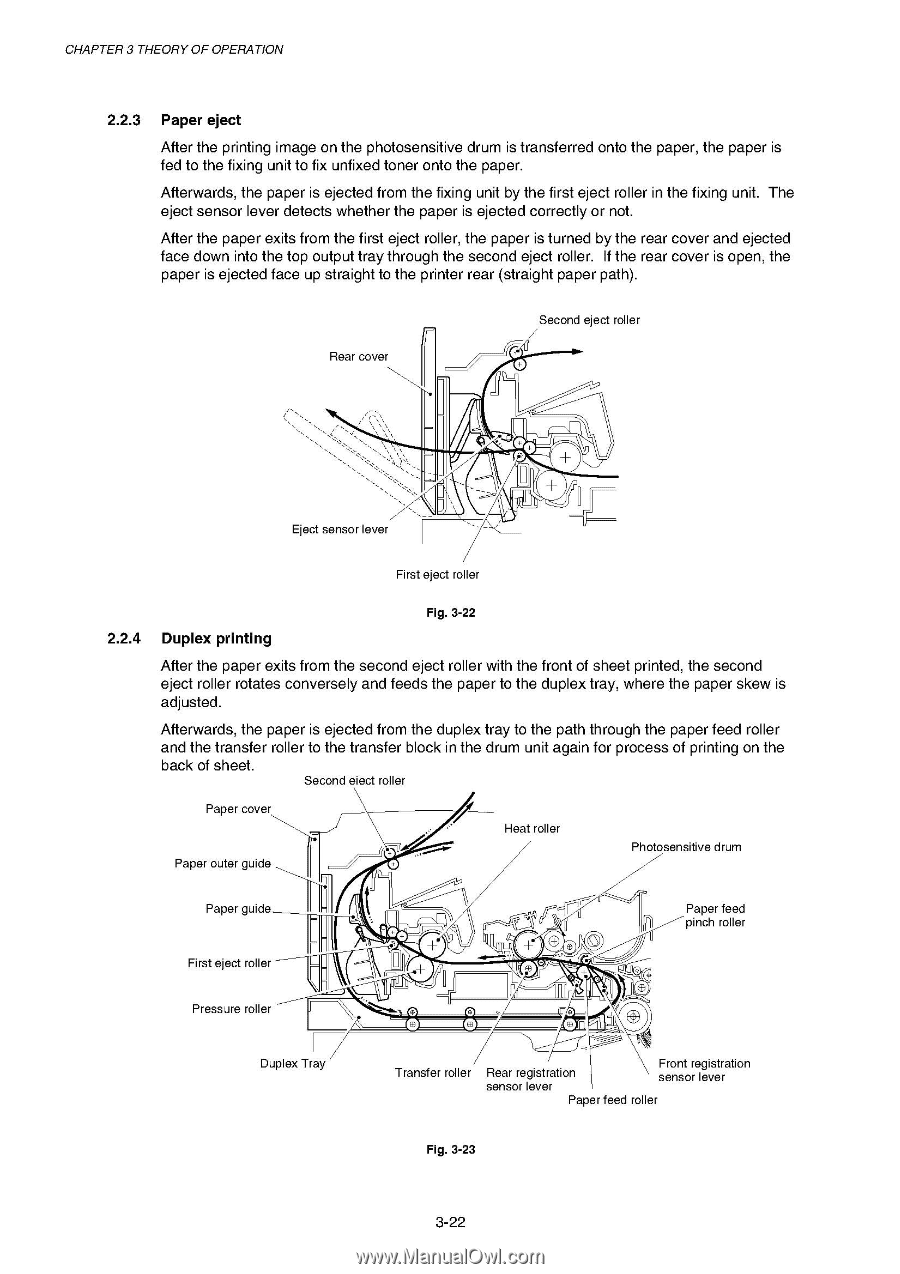

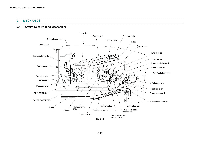

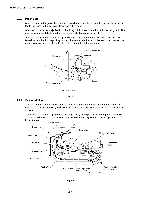

CHAPTER 3 THEORY OF OPERATION 2.2.3 Paper eject After the printing image on the photosensitive drum is transferred onto the paper, the paper is fed to the fixing unit to fix unfixed toner onto the paper. Afterwards, the paper is ejected from the fixing unit by the first eject roller in the fixing unit. The eject sensor lever detects whether the paper is ejected correctly or not. After the paper exits from the first eject roller, the paper is turned by the rear cover and ejected face down into the top output tray through the second eject roller. If the rear cover is open, the paper is ejected face up straight to the printer rear (straight paper path). Rear cover Second eject roller r + + + a + + Eject sensor lever First eject roller 2.2.4 Fig. 3-22 Duplex printing After the paper exits from the second eject roller with the front of sheet printed, the second eject roller rotates conversely and feeds the paper to the duplex tray, where the paper skew is adjusted. Afterwards, the paper is ejected from the duplex tray to the path through the paper feed roller and the transfer roller to the transfer block in the drum unit again for process of printing on the back of sheet. Second eiect roller Paper cover } Paper outer guide # + m Heat roller Photosensitive drum Paper guide First eject roller Pressure roller 0 + e G e e Paper feed P pinch roller Q e Duplex Tray Transfer roller Rear registration sensor lever Front registration sensor lever Paper feed roller Fig. 3-23 3-22