HP Designjet L28500 HP Designjet L28500 Printer Series - User's guide - Page 143

Troubleshoot substrate issues, The substrate cannot be loaded successfully

|

View all HP Designjet L28500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 143 highlights

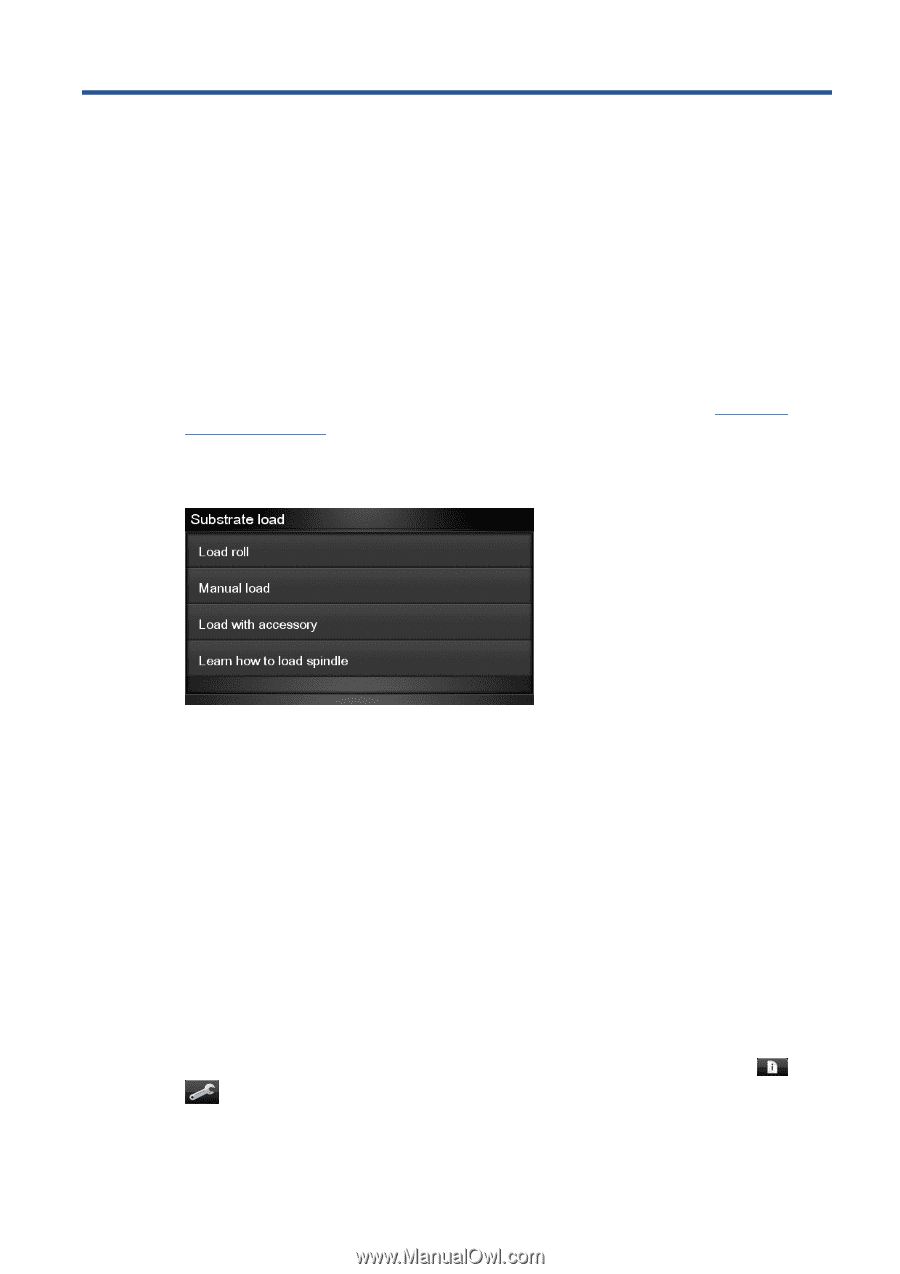

14 Troubleshoot substrate issues The substrate cannot be loaded successfully Here are some suggestions to try if you cannot load the substrate successfully. ● Reread the loading instructions, and make sure that you are following them. See Handle the substrate on page 21. ● When loading a textile substrate, remember to use the loading accessory, and select Load with accessory in the front panel. ● If automatic loading is unsuccessful, try manual loading instead. ● The substrate might be loaded at an angle (skewed or mislocated). Make sure that the right edge of the substrate is aligned with the roll on the input spindle. ● The substrate might be crumpled or warped, or have irregular edges. ● If the substrate jams in the substrate path to the platen, the leading edge of the substrate might not be straight or clean. Remove the initial 2 cm (1 in) of substrate from the roll and try again. This might be necessary even with a new roll of substrate. ● Make sure that the spindle is correctly inserted. ● Make sure that the substrate is correctly loaded on the spindle, and that it loads over the roll towards you. ● Make sure that the substrate is wound tightly. ● If the substrate is curled, and you see a Clean OMAS or disable it at the RIP alert, advance the substrate until the whole print zone is covered, then go to the front panel and press , then , then Ink > Image-quality maintenance > OMAS calibration. ENWW The substrate cannot be loaded successfully 137