HP Designjet L28500 HP Designjet L28500 Printer Series - User's guide - Page 170

Appendix A, Summary of common printing problems, Problem, Parameter, Change, Possible side-effects

|

View all HP Designjet L28500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 170 highlights

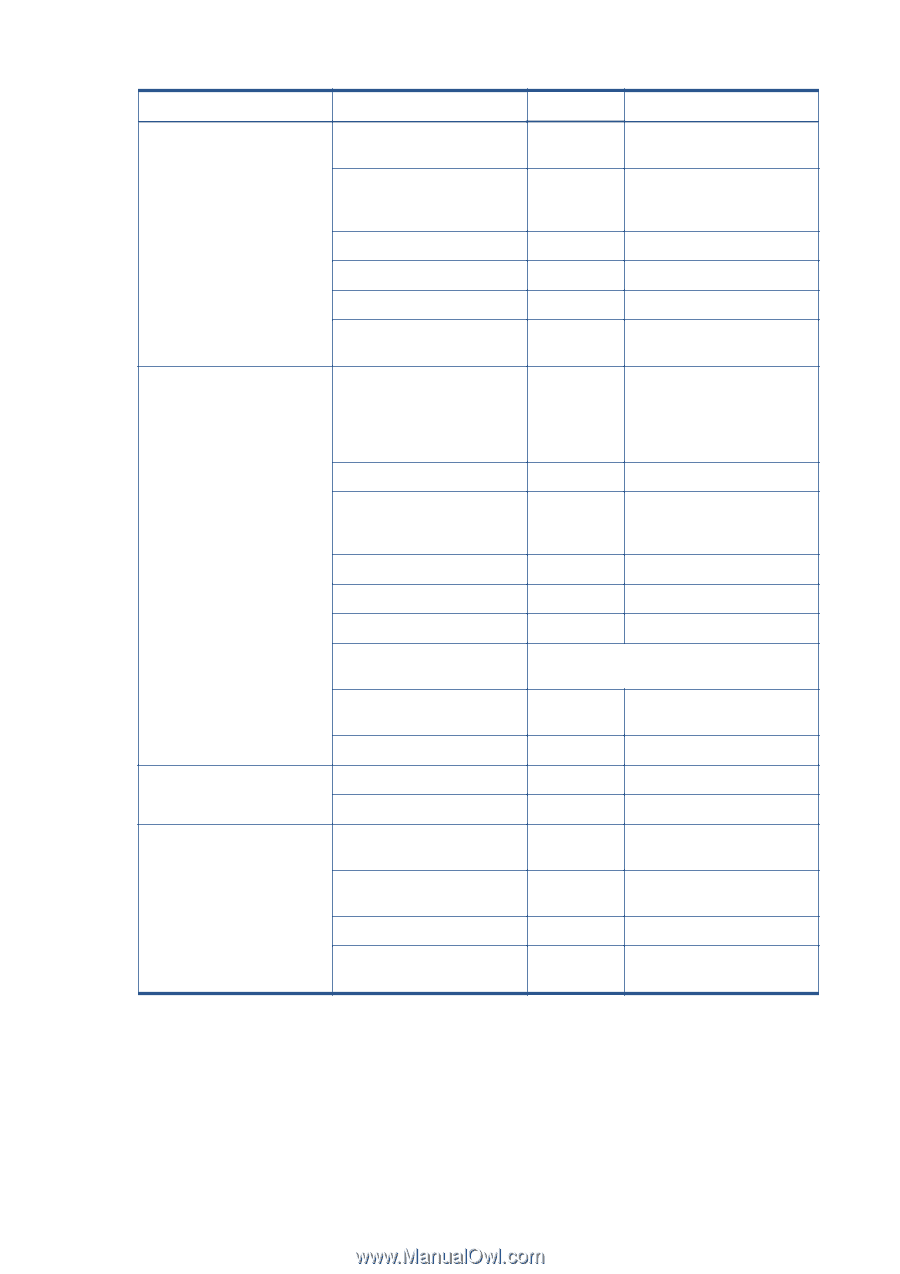

Problem Horizontal banding in saturated area fills Parameter Drying temperature Ink limits Inter-pass drying time Number of passes Carriage speed Modify color separations and dark color generation Vertical banding in low-to-medium Drying temperature area fills Align printheads Ink limits Inter-pass drying time DNX Take-up reel Modify the print queue Roll back tension Graininess, color misregistration or lack of sharpness Black areas look hazy or image gloss is not uniform Warming duration Align printheads Calibrate substrate advance Modify color separations and dark color generation Drying temperature Number of passes Curing temperature Change Increase Decrease (depends on RIP) Increase Increase Decrease Possible side-effects Substrate jam, substrate damage, ink smears Reduced color gamut Slower printing Slower printing Slower printing Decrease Slight color differences and/or horizontal banding at edges (increase inter-pass drying time/ number of passes or decrease carriage speed to fix this) Increase (depends on RIP) Increase Slower printing Activate Grainy aspect Use Avoid difficult areas at the end of the queue, and sudden changes of ink limits while printing Increase Grain and/or horizontal banding may appear if too high Increase Causes some delay Increase Increase Decrease Substrate jam, substrate damage, ink smears Slower printing Less durability (smudges), oily finish 164 Appendix A Summary of common printing problems ENWW