HP Designjet L28500 HP Designjet L28500 Printer Series - User's guide - Page 69

Temperature profile, Select the number of passes

|

View all HP Designjet L28500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 69 highlights

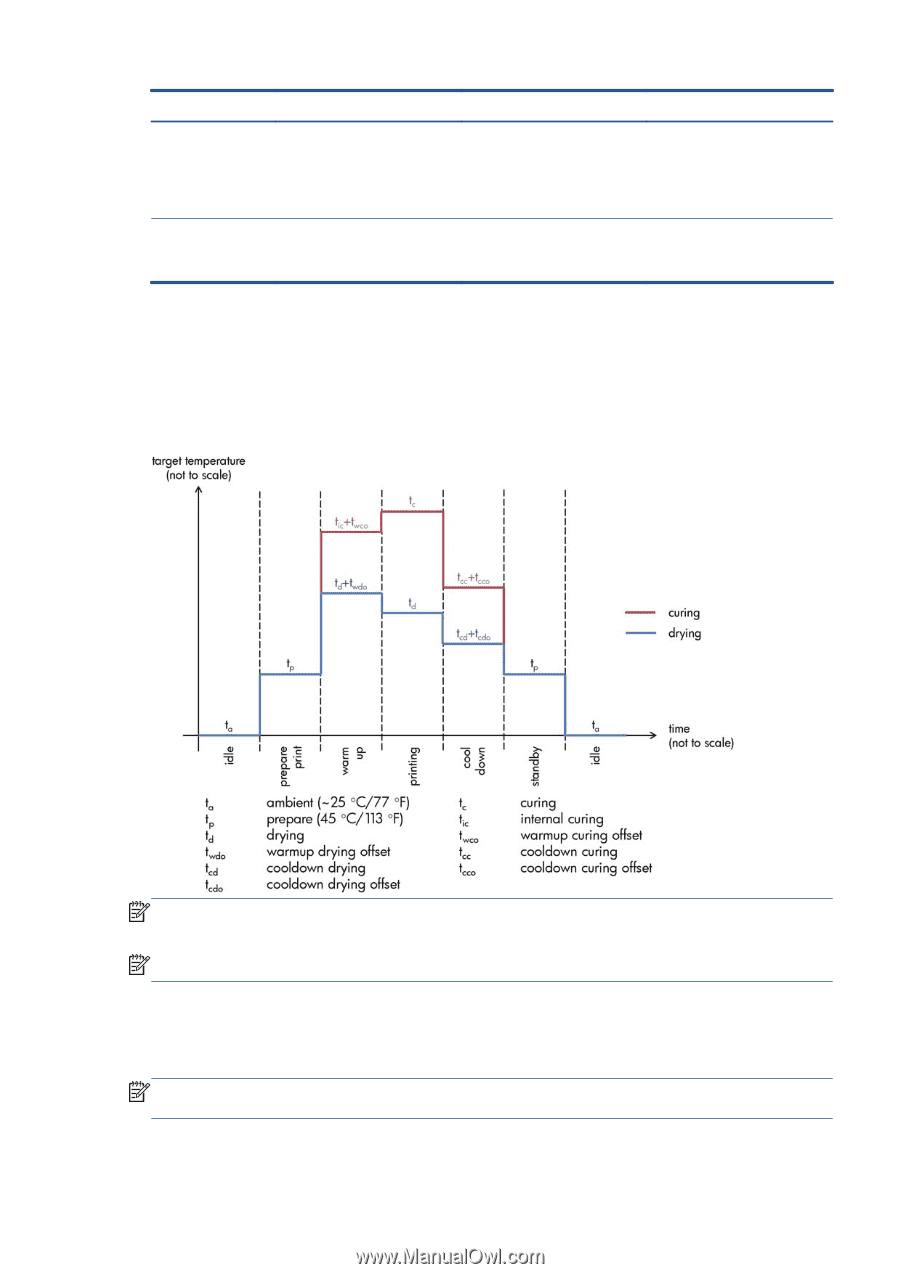

Setting Description If too low If too high Minimum drying power The minimum power applied in the drying module while printing, so the substrate does not cool too much in lightly inked areas. A heavily inked area that comes after a lightly inked area will have bleeding or coalescence defects. The substrate is damaged in blank or lightly inked areas of the print, especially with a high number of passes. Inter-pass drying time A delay between consecutive passes of the printhead carriage across the substrate. Drying and/or curing may not be sufficient in some cases. Printing is slower. Temperature profile Many of the main and advanced substrate settings are related to temperature control, since this is a critical area for correct printing results with latex inks on a wide variety of substrates. The diagram below graphically represents the evolution of drying and curing temperatures during the various printing phases. NOTE: Target temperatures and time are not to scale. For the specific values used for a given substrate type (family), consult the main and advanced settings tables above. NOTE: tp time can be modified through the printer's front panel. Select the number of passes Increasing the number of passes will tend to improve the print quality but reduce the speed of printing. NOTE: The following table is for bidirectional printing only, and with normal ink limit, unless otherwise indicated. ENWW Add a new substrate 63