HP LaserJet 9040/9050 Service Manual - Page 102

Cartridge memory, Toner seal, Toner-level detection

|

View all HP LaserJet 9040/9050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 102 highlights

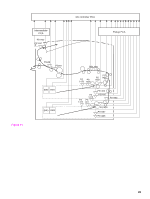

Cartridge memory The print cartridge comes with built-in RAM. The printer detects the cartridge condition by reading and writing to this memory. The read/write of the memory is performed by the memory controller after receiving instructions from the DC controller through the antenna unit. The DC controller instructs the memory controller PCA to perform read/write at the following timing: z Read • When the power is turned on • When the door cover is closed • When the DC controller receives a command from the formatter z Write • When a print operation is complete • When the DC controller receives a command from the formatter The DC controller also detects cartridge memory failures. If the DC controller fails in a read/write attempt two times, it reports the failure to the formatter as a cartridge memory abnormality. Toner seal This print cartridge incorporates an automatic toner-seal roll-up. When a new print cartridge is installed, the DC controller detects a new cartridge and sends a signal to the drum motor to roll up the toner seal. When a print cartridge is inserted, the power is turned on, or the door cover is closed, the DC controller monitors the toner seal opening detection signal and verifies whether or not the cartridge is new. If the cartridge is new, an open signal from the DC controller is sent to the drum motor. This reverses the drum motor rotation, which rolls up the toner seal. After a short period of time, the DC controller turns off the open signal, completing the roll up sequence. The DC controller also monitors the printer for presence of a print cartridge. When a cartridge is inserted, the same signal that instructs the cartridge to roll up the seal is used as a detection signal. Toner-level detection The print cartridge has built-in toner-level detection. The DC controller monitors the toner level using feedback signals received from two antennae (plate and flat) in the cartridge. When the power is turned on, a door cover is closed, or a print operation is performed, the DC controller sets the developing bias signal, the developing ac bias circuit sends a signal to the toner level circuit 1 and the developing cylinder. This causes the plate antenna to feedback the output value to the toner level circuit 1. The toner level circuit 1 compares the two signals and sends the results to the DC controller as the toner level detection signal. At the same time, the DC controller turns on the frequency output signal to output the reference frequency to the flat antenna. This causes the flat antenna to feedback the output value to the toner level circuit 2. The toner level circuit 2 compares the two signals and sends the results to the DC controller as the toner level detection signal, toner level accuracy to within 1% from 0 to 100%, then reports the result to the formatter. 86 Chapter 5 Theory of operation