Epson Stylus Pro 9000 Service Manual - Page 162

Paper Release Lever, 7.2.11 Interface, Print Area and Margin Optimization for Roll Paper

|

View all Epson Stylus Pro 9000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 162 highlights

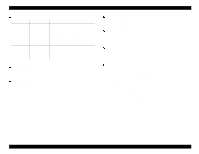

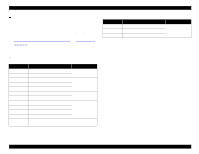

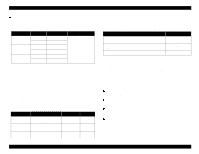

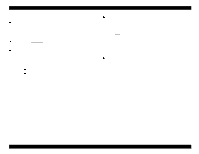

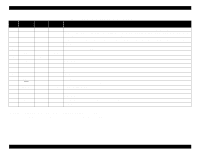

EPSON Stylus Pro 9000 Special paper For special paper meeting the following requirements, the feeding operation and print quality are optimized. Table 7-3. Specifications for Special Paper Paper Part Number Paper Size Roll Size Presentation matte paper Semi-gloss photo paper S041220 S041221 S041223 S041222 44 in. (1,118 mm) 36 in. (914 mm) 44 in. (1,118 mm) 2-inch core. Paper thickness (radius) of 3.9 inches (100 mm) or less. 36 in. (914 mm) Photo paper glossy S041224 S041225 44 in. (1,118 mm) 36 in. (914 mm) Use at normal room temperature: 59 to 77 °F (15 to 25 °C) 40 to 60% humidity Paper feeding is normal until the rear edge of the paper separates from the core. At the point where the rear edge is free, print quality is not guaranteed. Upper spindle 15.75 inches (last 400 mm) not guaranteed Lower spindle 11.8 inches (last 300 mm) not guaranteed For special paper meeting the following requirements, the feeding operation and print quality are optimized: Table 7-4. Special Paper Specifications Paper Dimensions (W x H) SuperFine* Glossy Film A3 11.7 × 16.5 in. (297 × 420 mm) OK OK2 A3 Wide 13 × 19 in. (329 × 483 mm) OK OK A2 16.5 × 23.4 in. (420 × 594 mm) OK - * Print quality optimized when printing unidirectional printing. 7.2.10 Paper Release Lever Table 7-5. Print Area and Margin Optimization for Roll Paper To Optimize For. . . . . .Select This Setting Largest printable area and decrease chance of paper rubbing printheads T/B15MM* Exact paper size and decrease chance of paper rubbing printheads 15MM Largest printable area and exact paper size 3MM If the paper release lever is down, the feed path is open and you can load, remove or change the position of paper in the feed path. If the paper release lever is up, the feed path is closed and loaded paper is locked in place. You can print on the loaded paper. It is not possible to change the lever position during printing. 7.2.11 Interface This section describes the interfaces for the EPSON Stylus Pro 9000. Transmission mode Based on RS-423 Synchronization Synchronous Transfer speed About 1.8 Mbps Data format Start bit: 1 bit Data bit: 8 bits Parity bit: None Stop bit: 1 bit Appendix 162