Epson Stylus Pro 9000 Service Manual - Page 25

Paper Width Sensor - carriage

|

View all Epson Stylus Pro 9000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

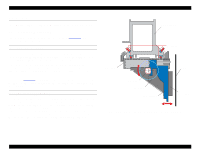

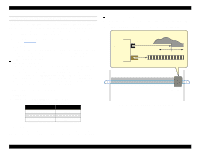

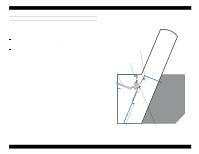

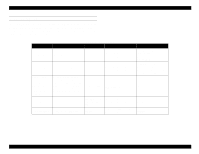

EPSON Stylus Pro 9000 To maintain a constant distance between the printhead nozzles and the paper, the printer measures the thickness of the paper and adjusts the height of the carriage accordingly. The printhead has three platen gap (height) settings, as described in the table below. Table 2-1. Platen Gap Settings Platen Gap Setting Gap Distance PG "Small" 1.3mm PG "Medium" 2.2mm PG "Large" 2.7mm The actual platen gap position used during printing depends on both the detected paper thickness and the user's paper thickness setting on the control panel. Table 2-2. Platen Gap Setting Determination Control Panel Setting Paper Thickness Sensor Platen Gap Position Wide Wide PG "Large" Standard PG "Medium" Auto Wide PG "Large" Standard PG "Small" The printer uses two sensors in setting the platen gap: Paper Thickness Sensor This sensor physically gauges whether the paper falls into the normal/thin category or the thick category. The Pressure Roller unit closest to home position has a thin metal flag on top. When the Paper Release Lever is in the Lock position and thin paper is loaded, this flag pivots into the space between the sensor's light emitter and receiver. However, when thick paper is loaded, the flag is forced forward out of the sensor area. Sensor signal = ON at 0.7 V or less: Normal or thin paper Sensor signal = OFF at 2.4 V or more:Thick paper PG Sensor This light-reflecting sensor detects whether the subcarriage is in the thick paper position or normal paper position. The PG Gear rotates with the PG Cam, and the PG Sensor determines the subcarriage's position from the position of the PG Gear, using the hole in the gear's side as a reference. PAPER WIDTH SENSOR This sensor locates the right and left edges of the paper. The light emitted from the sensor is reflected back to the sensor where paper exists. In this way the sensor determines where the paper's edge is and how wide the paper is. Carriage Left edge Right edge Paper Width HP side sensor Paper Figure 2-6. Paper Width Sensor Technical Overview 25