Brother International ZE-856A Instruction Manual - English and Spanish - Page 225

Troubleshooting, Fehlersuche, Resolution Des Problemes, Localizacion De Averias, Problem, Possible

|

View all Brother International ZE-856A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 225 highlights

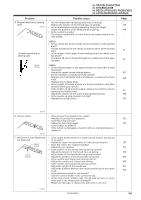

Problem 5. Skipped stitches at sewing start 0622M Thread unravelling at sewing start Upper thread 16. TROUBLESHOOTING 16. FEHLERSUCHE 16. RESOLUTION DES PROBLEMES 16. LOCALIZACION DE AVERIAS Possible cause • Are the thread take-up spring tensions too strong? Reduce the tension of the thread take-up springs. • Is the thread tension spring operating range too large? Lower the position of the thread tension spring. • Is the needle too wide? Try using a needle with a count that is one lower than the current needle. Page 145 144 - • Is the needle bar at the needle up stop position at the sewing start? Set the needle bar to the needle up stop position at the sewing start. 51 • Is the length of the upper thread trailing from the needle hole too short? Pull about 50 mm of thread through the needle hole at the sewing start. 52 • Is the trailing length of the upper thread too short after thread trimming? Adjust the upper thread feeding device. 161 • Are the threads not being trimmed cleanly? Sharpen the fixed knife with a whetstone, or replace the fixed knife. 138 Replace the movable knife. • Is the length of thread trailing out from the bobbin case after thread trimming too short? If the bobbin is spinning loosely, replace the bobbin tension spring in the bobbin case. 47 Adjust the tension of the lower thread presser spring. 169 • Is the needle up stop position too high? Adjuste the synchronizer. 157 0623M 6. Uneven seam 0625M 7. Horizontal thread tightening not balanced Upper thread Lower thread • Is the presser foot pressure too weak? Adjuste the presser foot pressure. • Is the feed dog too low? Adjust the feed dog height. • Is the bobbin scratched? If the bobbin is damaged, smooth it with an oiled grindstone or replace it. • Is the upper thread tension or lower thread tension too strong or to weak? Adjust the upper thread tension or lower thread tension. • Does the rotary disc rotate smoothly? Adjust the pre-tension. • Is the tension of the thread take-up spring correct? Adjust the tension of the thread take-up spring. • Is the stroke of the thread take-up spring correct? Adjust the position of the thread take-up spring. • Is the needle and rotary hook timing correct? Adjust the needle and rotary hook timing. • Is the needle and rotary hook timing correct? Adjust the height of the needle bar. Adjust the distance between the needle and the tip of the rotary hook. • Is the thread too thick for the needle? Use the correct needle or the correct thread. • Is the rotary hook, bobbin case, thread take-up lever or some other part in the thread path damaged? Repair the damage, or replace the part with a new one. 0626M ZE-855A,856A 132 147 - 130 131 145 144 150 151 153 - - 206